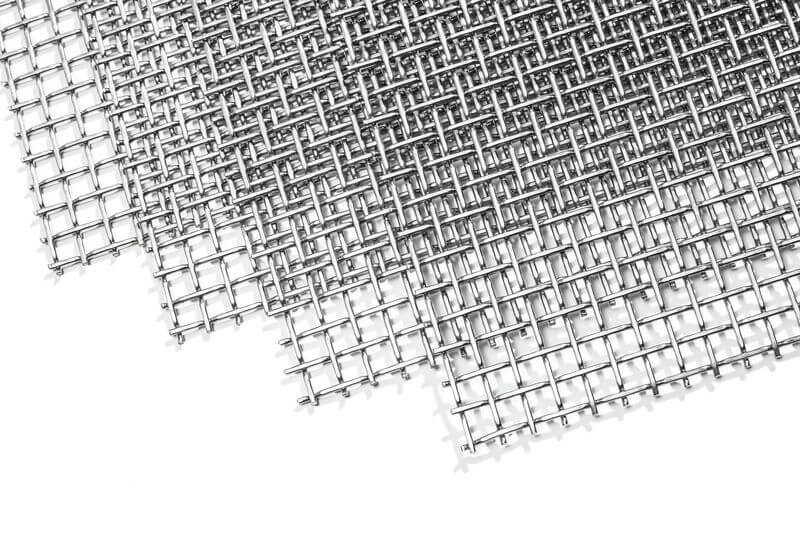

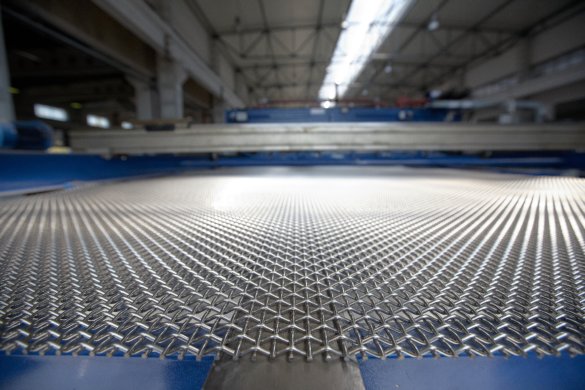

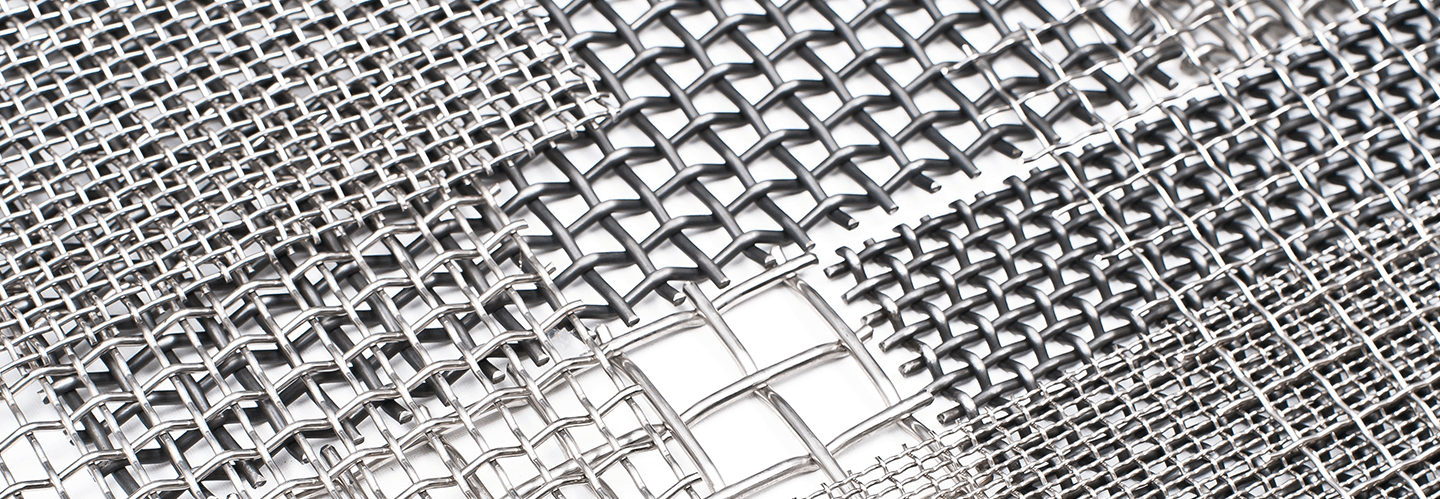

Do you need high performance screens for large grain size materials? Use the flat surface of the TL pressed screens. Thanks to the special weaving of the weft and warp wires, these screens are an excellent alternative to perforated and welded screens.

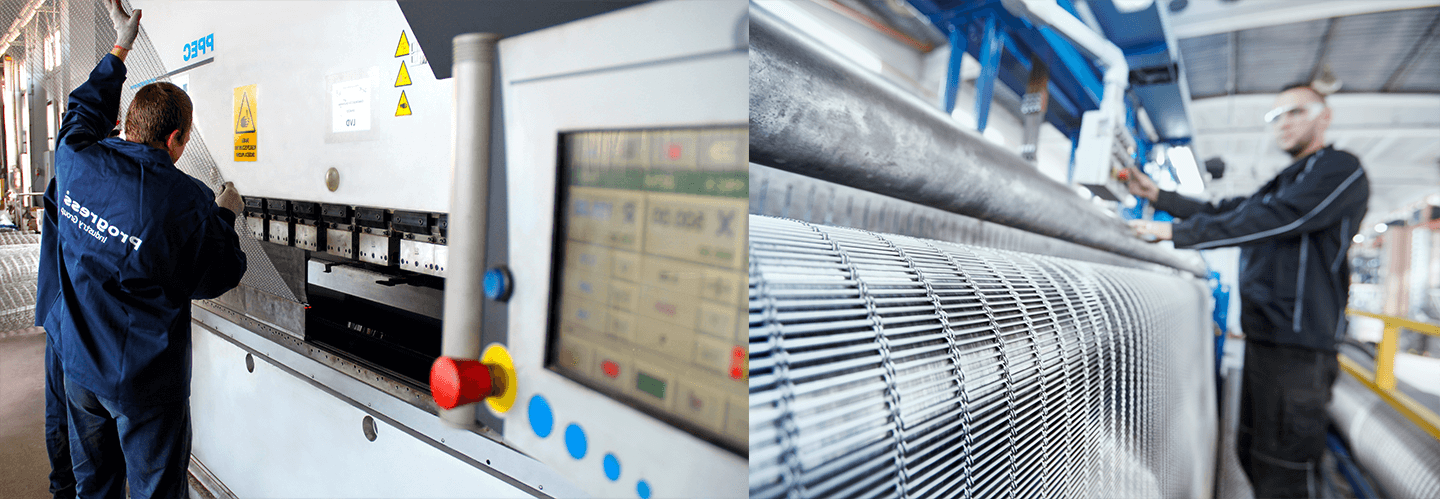

PROGRESS SCREENS™ provides solutions for machines and devices in the form of sheets and screens for mounting on all types of sifters and sorters. They are also perfectly suited for hardening shops and as structural and safety components.