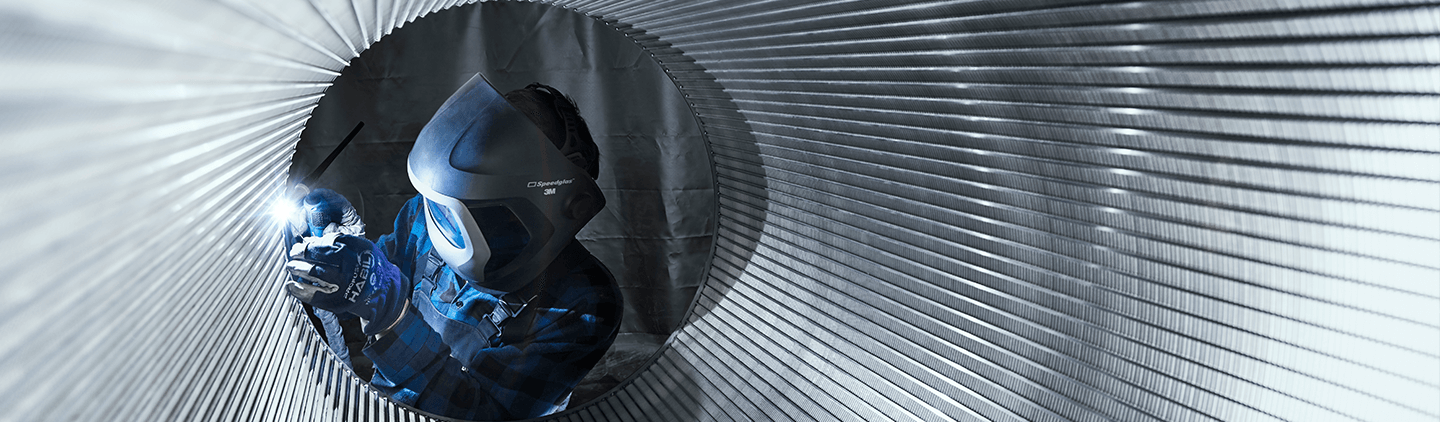

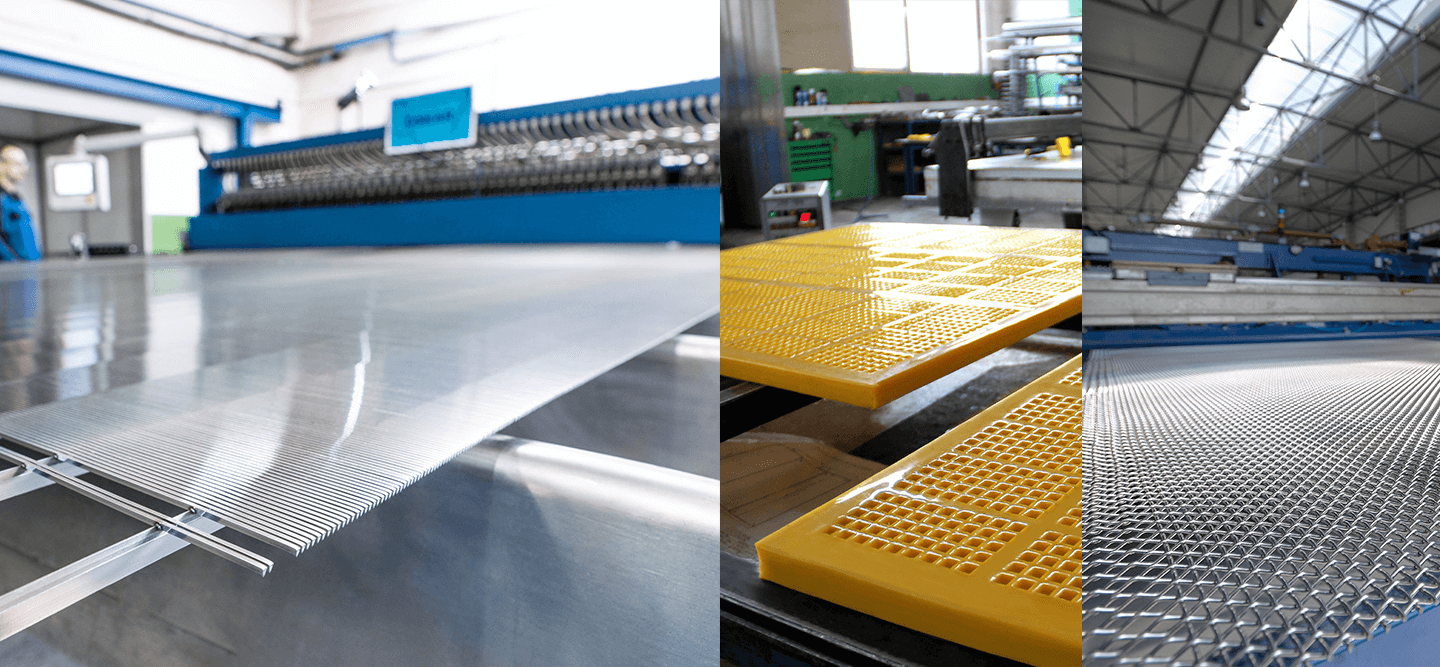

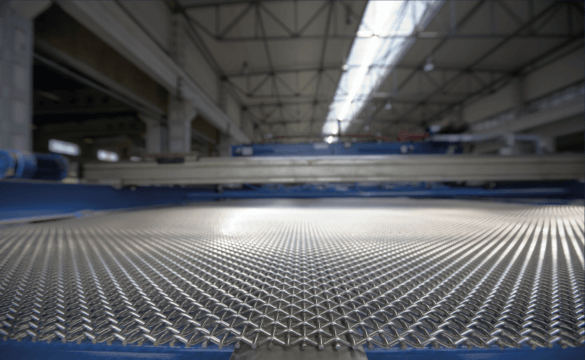

We specialise in the design and manufacture of industrial screens.

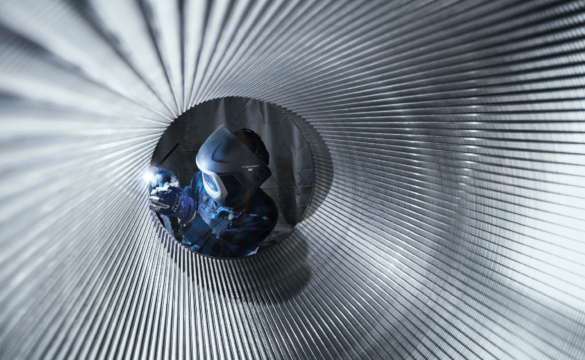

Since 1988, our solutions have been improving the technological processes of customers from many industries around the world, helping them to achieve optimal product parameters. We specialise in the design and manufacture of industrial screens, cartridges and filter elements, baskets for centrifuges and parts of machines and devices with their use.