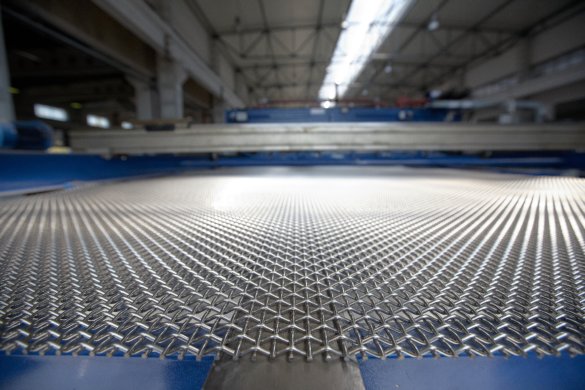

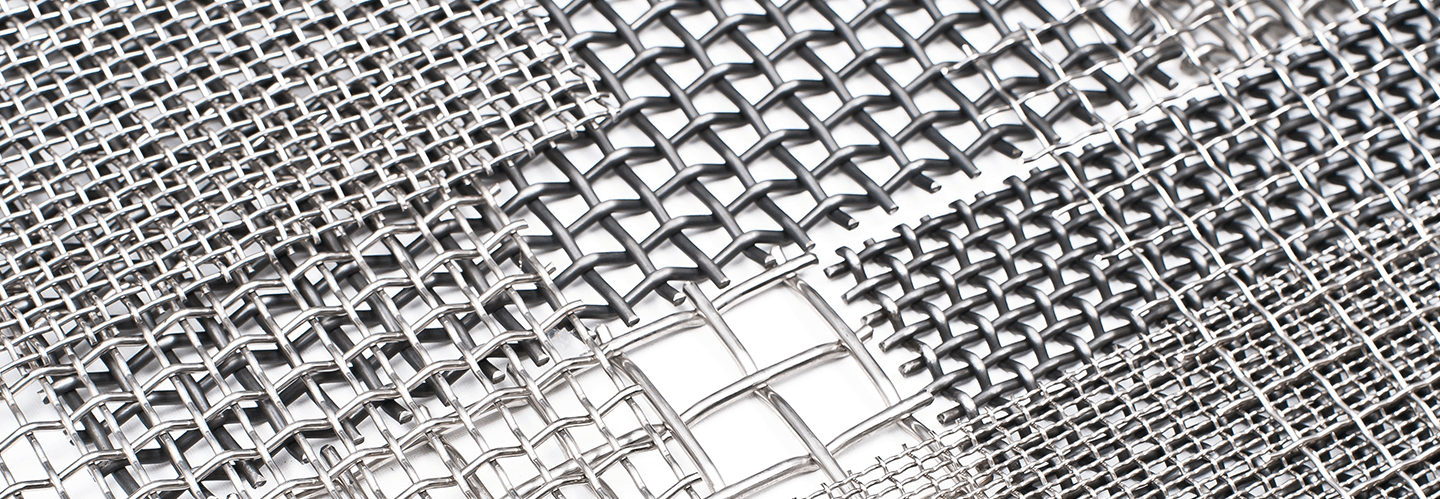

Do you need screens for screening and grading materials with a high tendency to stick? Use the unique structure of PROGRESS String Screens. The slotted shape of the eyelets and the use of simple round wires ensures maximum sieve performance. PROGRESS SCREENS® provides complete screens for longitudinal mounting on all types of screens and sorters.

Products

Back

String screens

Piano screens for sand screening

Piano screens for sand screening

Piano screens - rubber patches

Piano screens - rubber patches

Piano screens - metal patches

Piano screens - metal patches

Harp screens in polyurethane frame

Harp screens in polyurethane frame

PROGRESS SCREENS™ Applications

Screens for sorters

Screens for calibrators

Industries

Product advantages

Take advantage of PROGRESS string

screens in screening and classification processes:

- Slit shape of openings

- Self-cleaning effect

- High ratio of open area

- A system of movable patch

- Extended lifetime

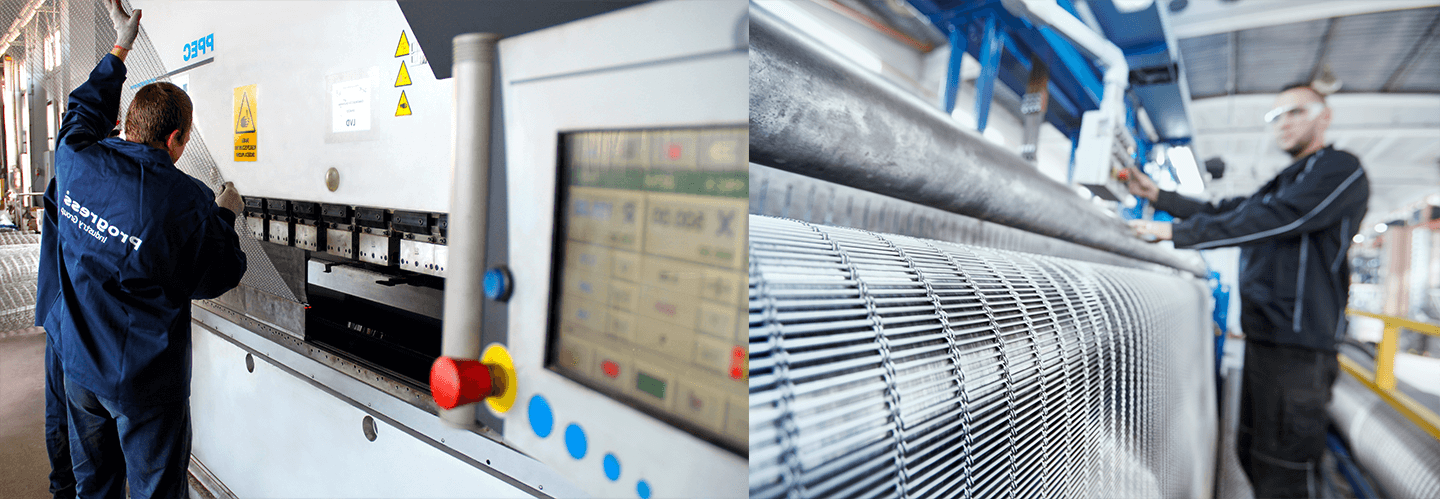

Manufacturing technologies

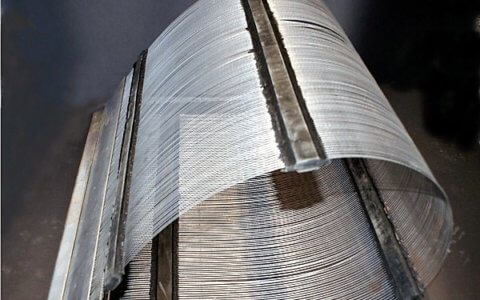

Using specialised knowledge and a modern machine park, we can manufacture stringed screens with sliding and non-sliding polyurethane and rubber bands.

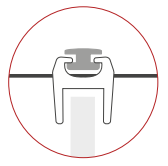

TYP PU

Polyurethane lacings non-sliding for fastening on ridges of sifters where the supports are covered are rubber profiles.

TYP S

Sliding lacings for mounting on ridges screens where supports are flat bars.

TYP R

Sliding lacings for mounting on ridges screens where supports are pipes.

Parameters

For the improvement and development of product and material solutions, we use the experience of our engineers and our own Research and Development Centre.

Currently, we offer PROGRESS string screens with openings of 1.2 – 55 mm and wire diameters of 0.8 – 8.0 mm.

We provide detailed technical information in respect of individual requests.

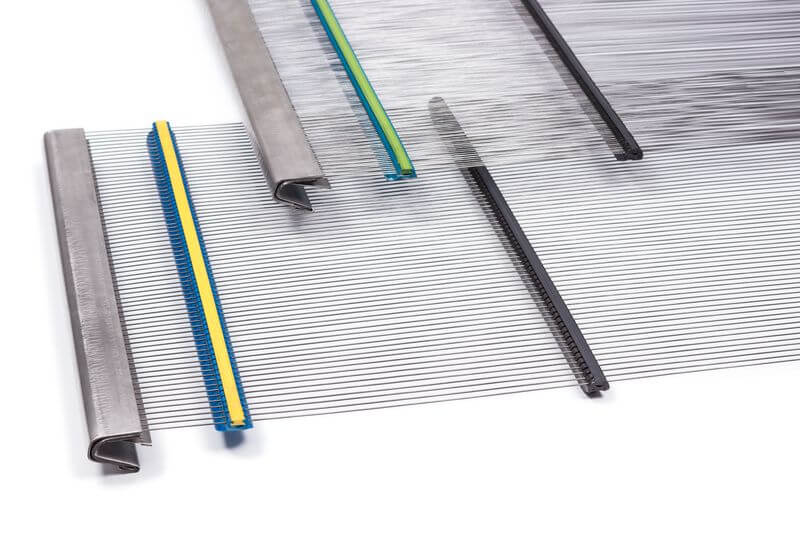

Ferrules and finishes

A wide range of brackets for longitudinal tension ensures correct installation of PROGRESS string screens on all types of vibrating sifters and sorters. In the case of TYP-PU non-sliding bands, it is necessary to precisely determine the spacing of the supports. In other types of string screens, it is enough to specify the number and type of bands. Their adjustment takes place during assembly on the sifter.

Materials

The woven screens used in various conditions require the use of the highest quality spring and stainless steel, as well as hard wearing abrasive bands. Their immediate accessibility is ensured by our material policy, and optimal selection by the support of our Construction and Technology Department.