Do you need durable and abrasion-resistant screens? Are you tired of fighting corrosion? Use the potential of polyurethane screens. Elastomer used for their production provides extended screen life, which work up to 10 times longer compared to steel screens. Invest and reduce the number of costly downtimes. PROGRESS SCREENS™ provides solutions for all types of sifters and sorting equipment for ‘dry’ and ‘wet’ work.

Products

Products

TENSIONED SCREENS AND POLYURETHANE MATS

Tensioned polyurethane screens - Pro-FALC

Tensioned polyurethane screens - Pro-FALC

Polyurethane screens for wet screening

Polyurethane screens for wet screening

Polyurethane screens - square mesh

Polyurethane screens - square mesh

Polyurethane screens - square mesh

Polyurethane screens - square mesh

PROGRESS SCREENS™ Applications

Rotary drum screens

Screen decks

Industries

Product advantages

Use the potential of polyurethane screens in screening and classification processes:

- ‘wet’ and ‘dry’ work

- Resistance to abrasion and absence of corrosion

- Noise and dust reduction

- Possibility of exchanging individual modules

- Simple assembly and disassembly of modules

- Assembly systems

Assembly systems

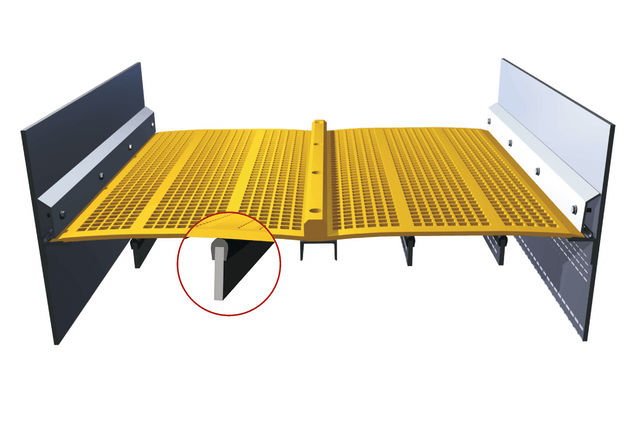

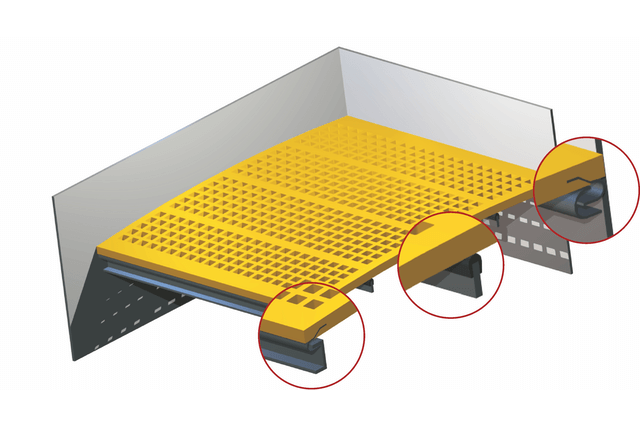

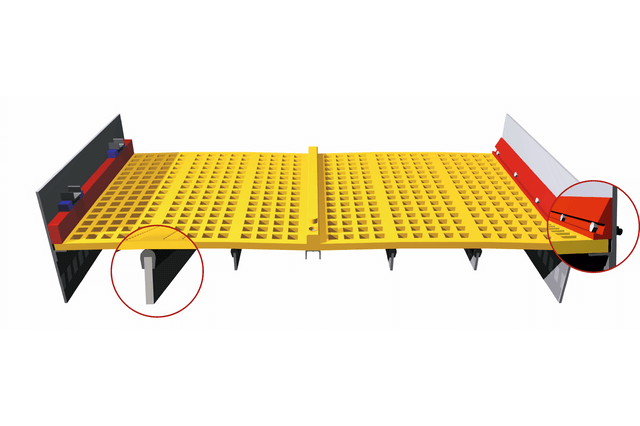

Incorrect screen assembly can shorten its life by up to 90%. PROGRESS SCREENS™ provides solutions for all types of sifting and sorting equipment. The assembly of polyurethane tensioned screens is carried out without changing the stitch, directly in place of the steel screens. We offer a full range of ferrules and hooks for transverse and longitudinal mounting. In their selection and preparation of appropriate surges and securing the traverse, you will be advised by our sales engineer.

Pro-FALC® polyurethane screens

Tensioned polyurethane screens with transverse stretch

Pro-FALC® polyurethane screens

Tensioned polyurethane screens with longitudinal stretch

Pro-MAT® polyurethane screens

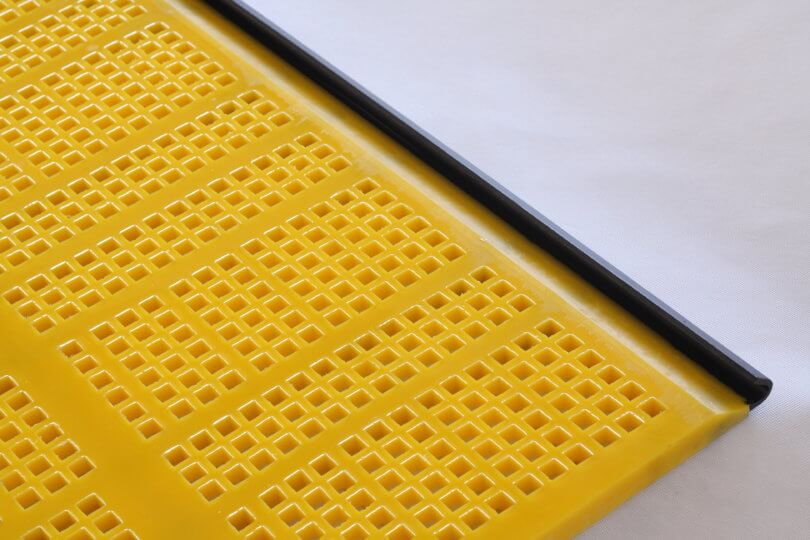

Polyurethane segmented screens fastened with a clamping strip.

Parameters

Using a modern machine park, we offer modular polyurethane screens in the openings range from 1.1 – 160 mm. The offer includes square and rectangular opening screens in a simple and passing layout.

The maximum screen dimensions are 1900 x 30000 mm. The dimensions are adapted according to the dimensions of the sifter or sorting machine. The standard screen thickness is 20 – 60 mm.

We provide detailed technical information in respect of individual requests.

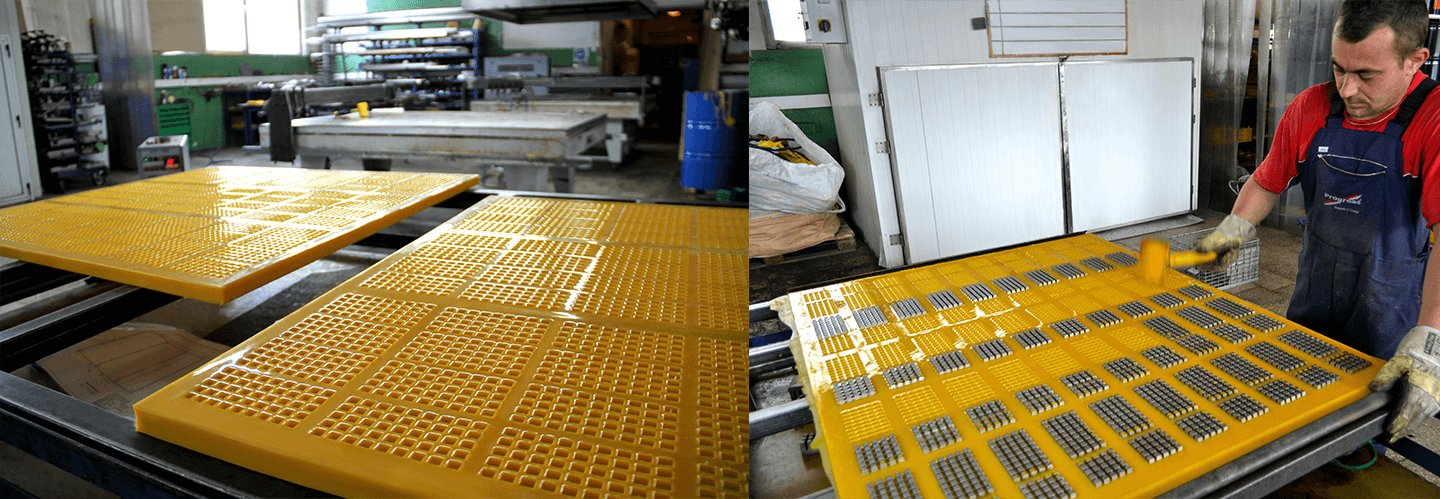

Reinforcements

Polyurethane screens are among the most durable industrial screens. Still, they cannot withstand particularly difficult working conditions and loads. We have a solution for this. PROGRESS SCREENS™ offers the possibility of using additional reinforcements in the form of cable wires, rods and flat bars that are specially embedded in the screens. The polyurethane surface is manufactured as one piece.

Materials

Polyurethane screens operating under various conditions require the use of appropriate elastomers and optimal hardness. PROGRESS SCREENS™ offers solutions using polyurethane elastomers type A and B in the hardness range 45-95 Sh. Benefit from the advice of our sales engineer.