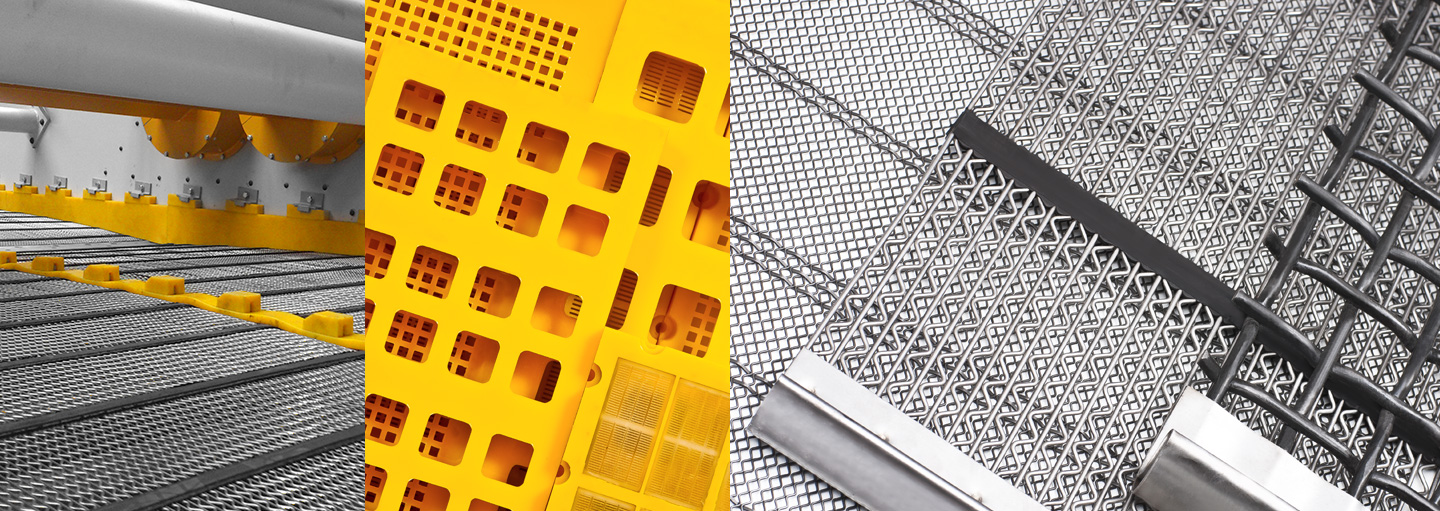

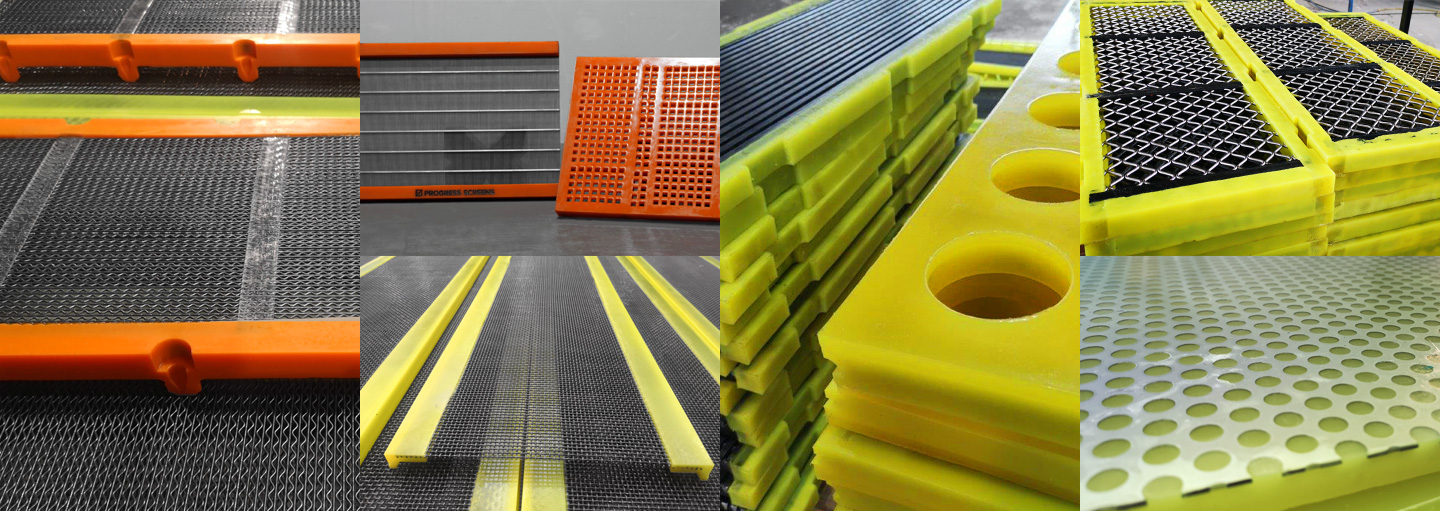

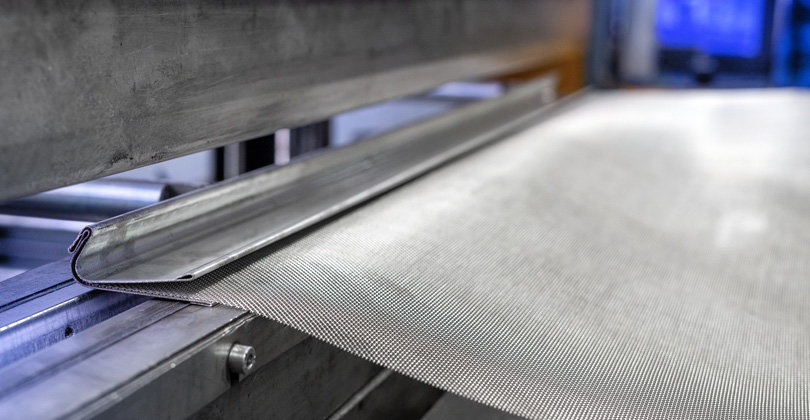

We provide all-inclusive services to quarries, mines, sand pits and gravel pits.

Take advantage of over 30 years of experience in the screening, classification and dewatering processes in the mineral resources industry and in the production of bituminous masses and construction chemicals. Opt for screens and screen decks installed by well-established machine manufacturer brands as original equipment of vibrating screens and separators.