Do you need small screens for precise filtration and separation processes? Use the potential of PROGRESS woven screens. Properly chosen weaves, the highest quality steel and a wide range of openings and wire diameters guarantee their effective work. PROGRESS SCREENS™ provides solutions for machines, devices and filters in the form of coils, sheets, ferruled screens and screens with brackets for mounting on all types of sifters and sorters.

Products

Back

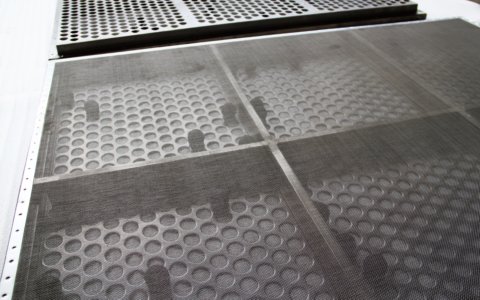

Woven screens

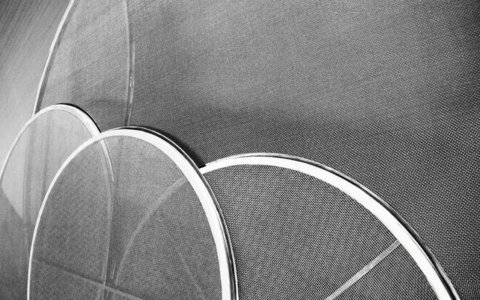

Fine wire mesh discs

Fine wire mesh discs

Rotary drum screen

Rotary drum screen

Filter cartridges based on fine wire mesh

Filter cartridges based on fine wire mesh

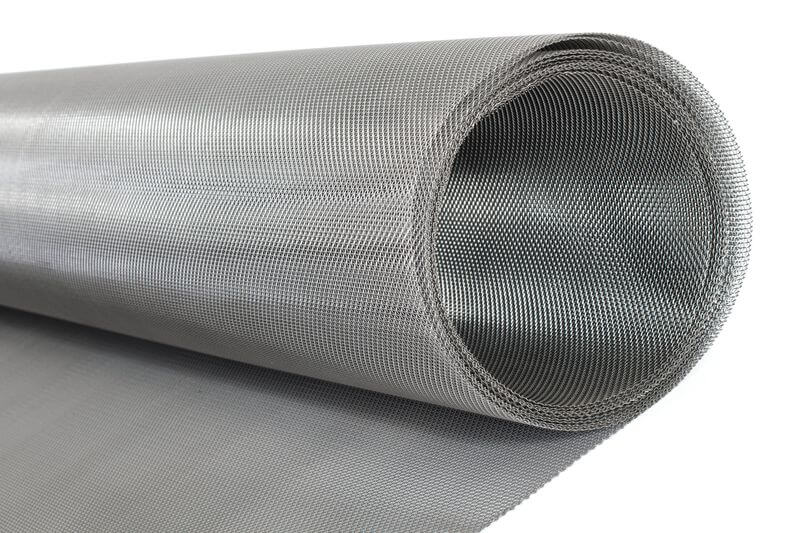

Fine wire cloth

Fine wire cloth

Fine wire mesh rotary drum

Fine wire mesh rotary drum

Screen frames for separators

Screen frames for separators

Screen frames for separators

Screen frames for separators

Filter cartridges based on fine wire mesh

Filter cartridges based on fine wire mesh

PROGRESS SCREENS™ Applications

Screens for sorters

Screens for calibrators

Screen frames

Wedge wire baskets and accessories for hardening

Filtration discs

Filtration inserts

Security grilles

Screen decks

Water and sewage

Product advantages

Use the potential of PROGRESS woven screens in screening and filtration processes:

- Accurate segregation of the screened material

- High efficiency of filtration processes

- High ratio of open area

- Precise opening dimensions

- Wide range of openings and wire diameters

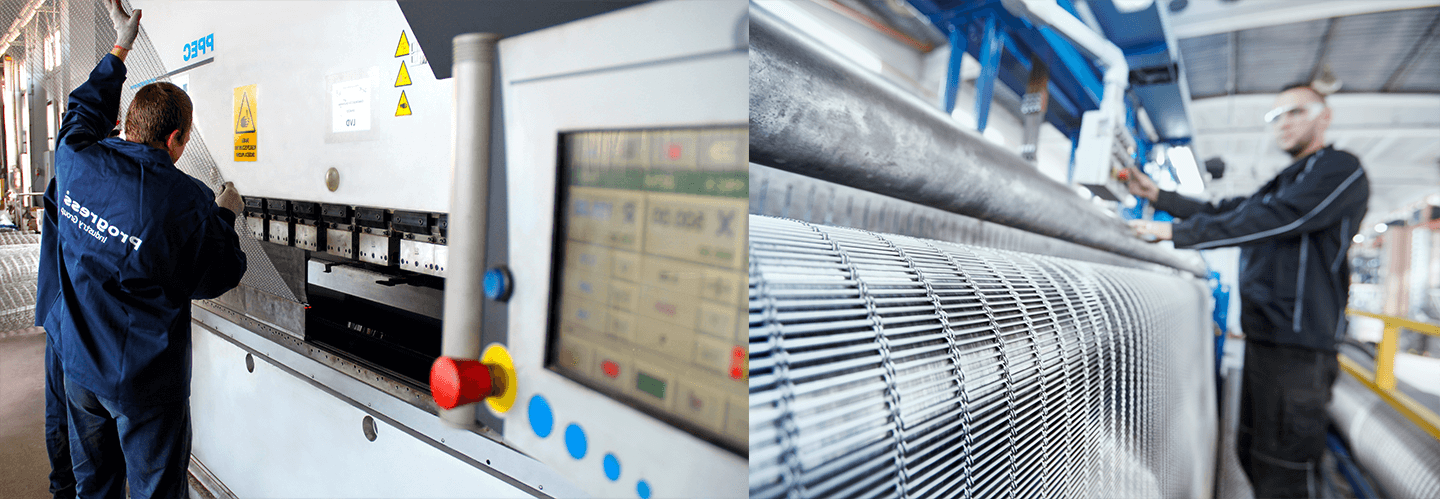

Manufacturing technologies

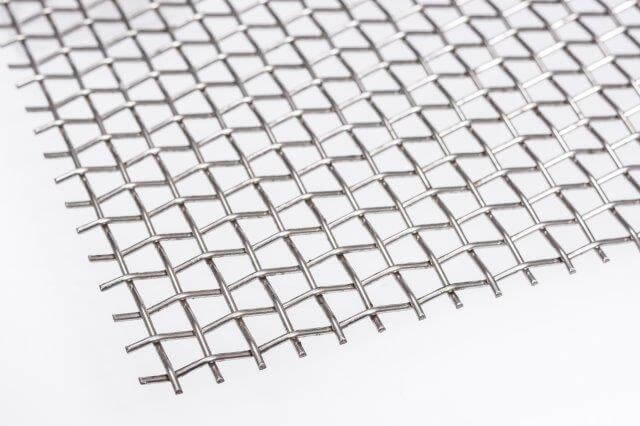

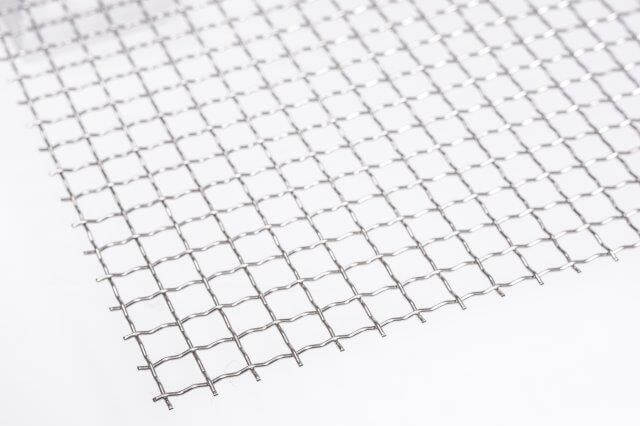

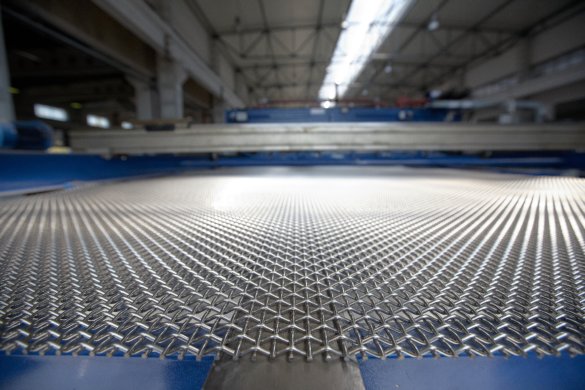

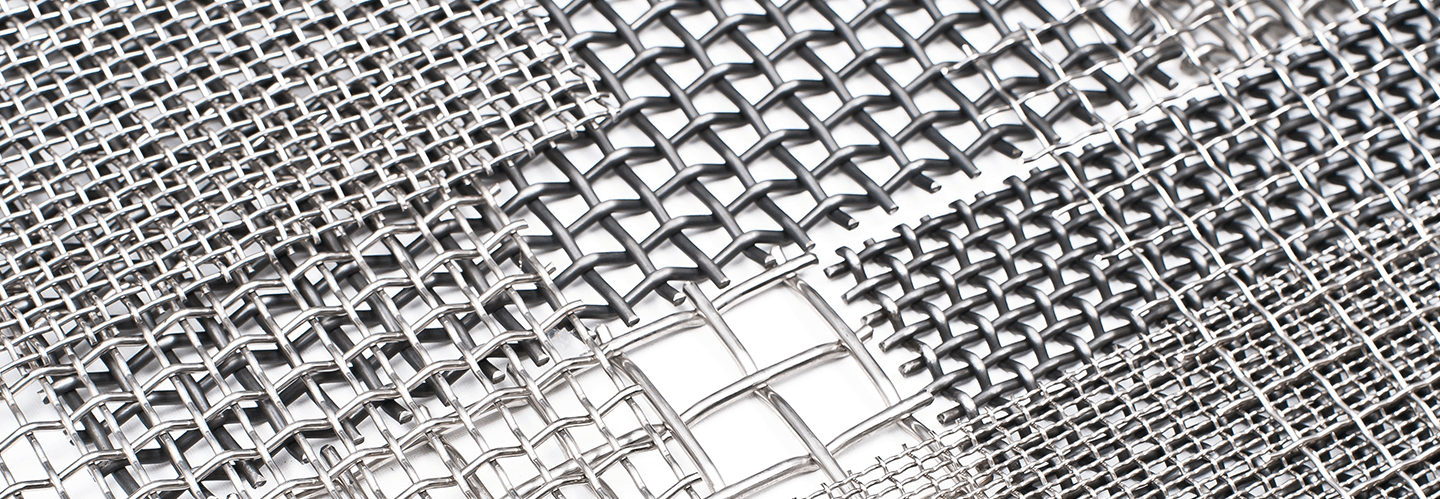

Using specialised knowledge and a modern machine park, as well as our know-how, we manufacture woven screens in plain (linen) and oblique (herringbone) weave and in the form of meshless screens.

Woven wire screens – single (plain) weave.

Woven wire screens – Twill (herringbone) weave.

Parameters

For the improvement and development of product and material solutions, we use the experience of our engineers and our own Research and Development Centre. Currently, we offer PROGRESS woven screens in the mesh range from 0.02 mm and wire diameter 0.02 – 1.2 mm. Maximum width of woven sieves is 4000. On special request of the Customer we make screens with wires of different diameters of weft and warp. We provide detailed technical information in respect of individual requests.

Ferrules and finishes

A wide range of taps for transversal and longitudinal tension ensures proper installation of PROGRESS woven screens on all types of vibrating screens and sorters machines. Depending on the application, PROGRESS SCREENS™ offers a wide range of screen processing, including cutting, formatting, shaping, and crimping.

Materials

The woven wire meshes used in different conditions require the use of the highest quality black, stainless, acid-resistant, heat-resistant and kanthal, inconel or duplex steel. Their direct accessibility is ensured by our material policy, and the optimal selection and support of our Construction and Technology Department.