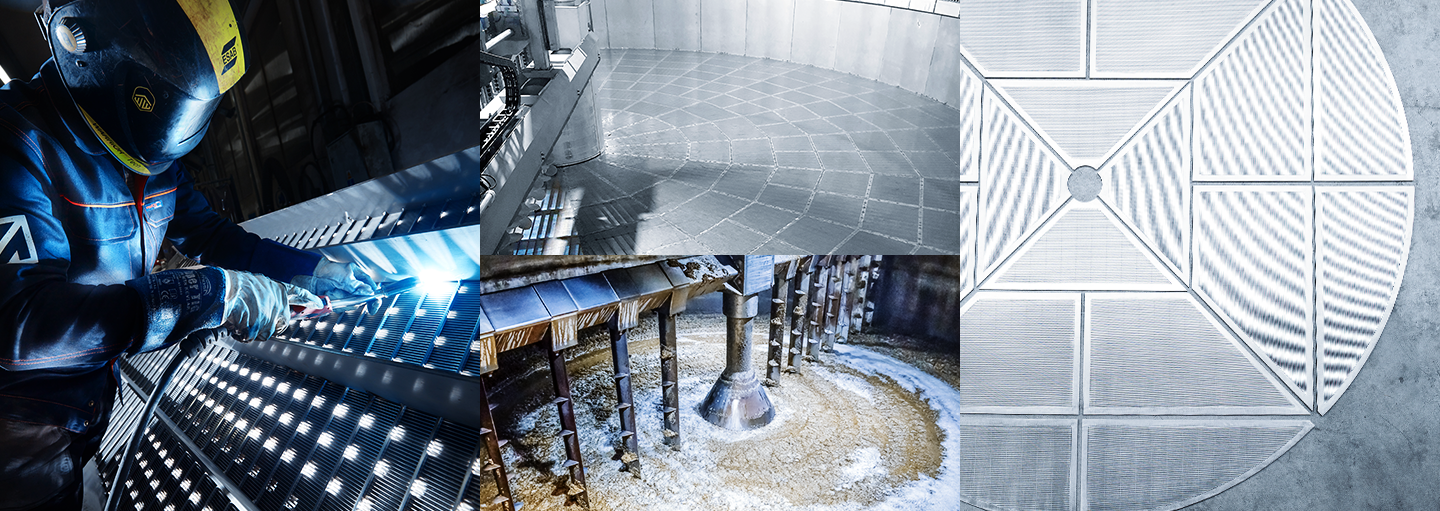

We provide comprehensive support for breweries, malthouses, and OEMs.

Benefit from our experience and solutions. Improve efficiency and optimise production costs in brewing and filtration, steeping, germination and malt drying processes. Count on wedge wire floors installed as original equipment by leading OEM equipment manufacturers and process lines.