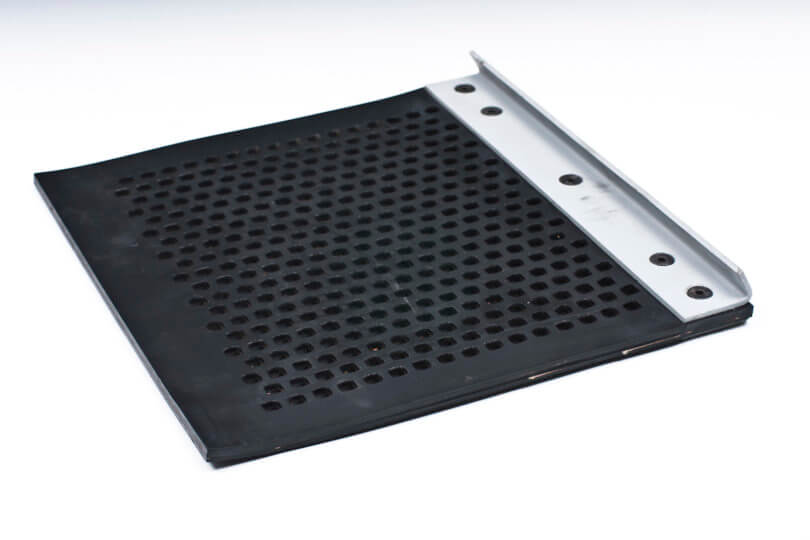

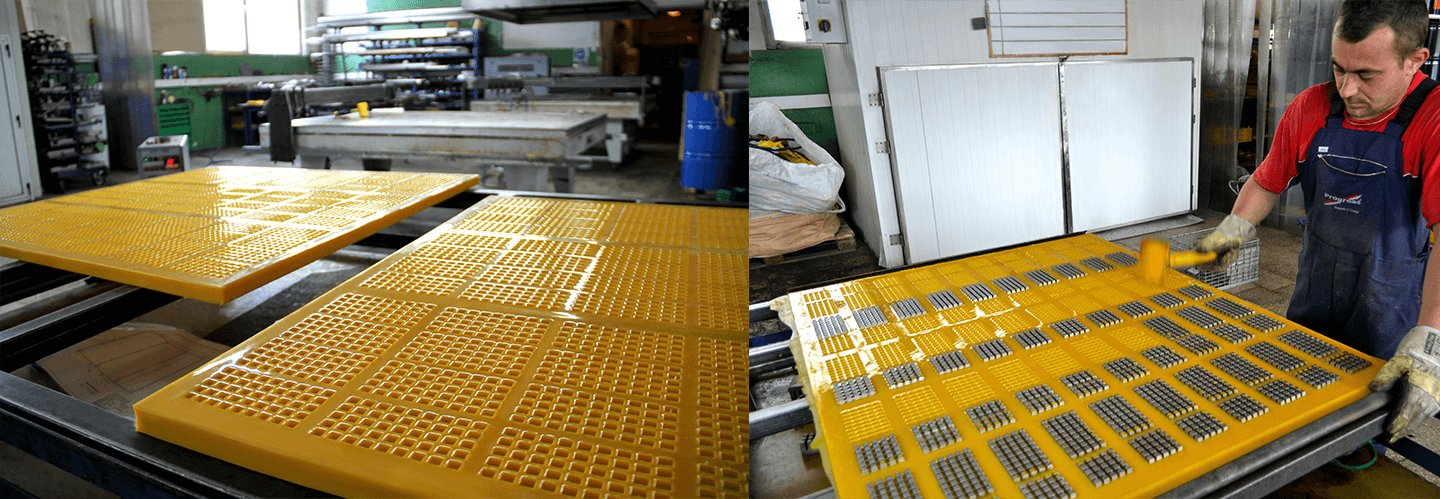

Do you need durable and abrasion-resistant screens? Do you want to reduce your operating costs? Use the potential of Pro-GUM™ rubber screens.

The use of high-quality abrasion-resistant rubber mixtures increases the lifetime of the screens. High efficiency of screening processes results from self-cleaning properties (vibrating membrane effect). PROGRESS SCREENS provides solutions for all types of sifters and sorting equipment.