We have a wide range of screen frames for separators and vibrating screeners. Our production capabilities allow us to deliver our solutions to virtually all industries, including the food and pharmaceutical industries, using materials with the appropriate certificates and required approvals. In the production process we use our own woven, fine wire and perforated sieves. Using the experience gained and stock of our screens, we also offer a complete service of sieve frames.

Sieve frames

Back

Sieve frames

PROGRESS SCREENS™ applications

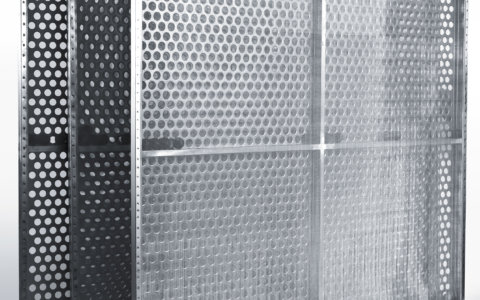

Screens for screening machines

Screens for sorters

Product advantages

Make use of the potential of PROGRESS screen frames

in your screening and classification processes

- Regeneration and cleaning options

- A high open area ratio

- No blanking

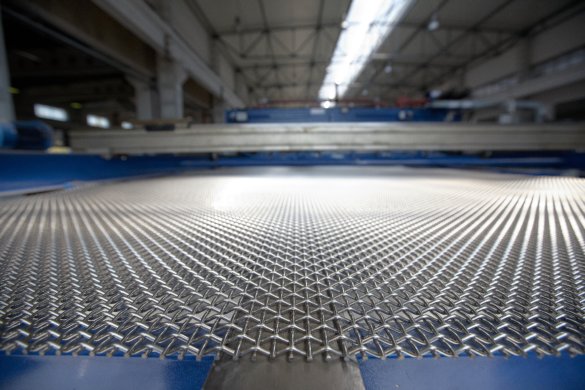

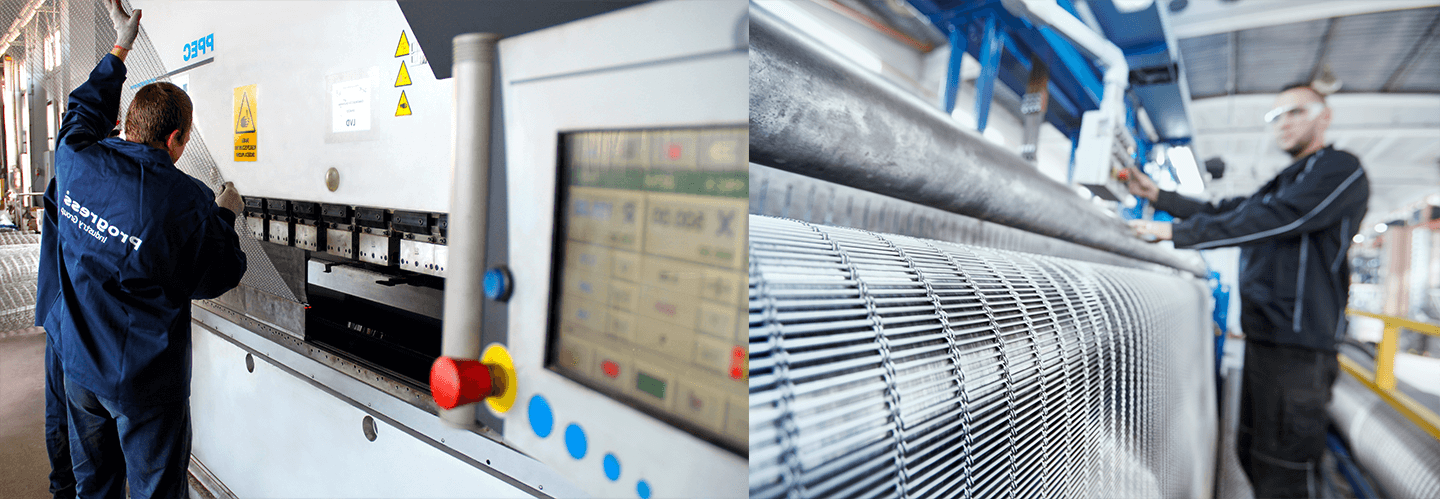

Production technologies

Using our expertise and state-of-the-art machine park, we manufacture round and rectangular screen frames for all types of screening machines and sorters.

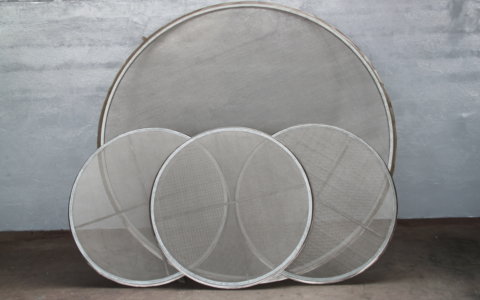

Round screen frames

There is an option to regenerate frames using woven and mesh screens we make.

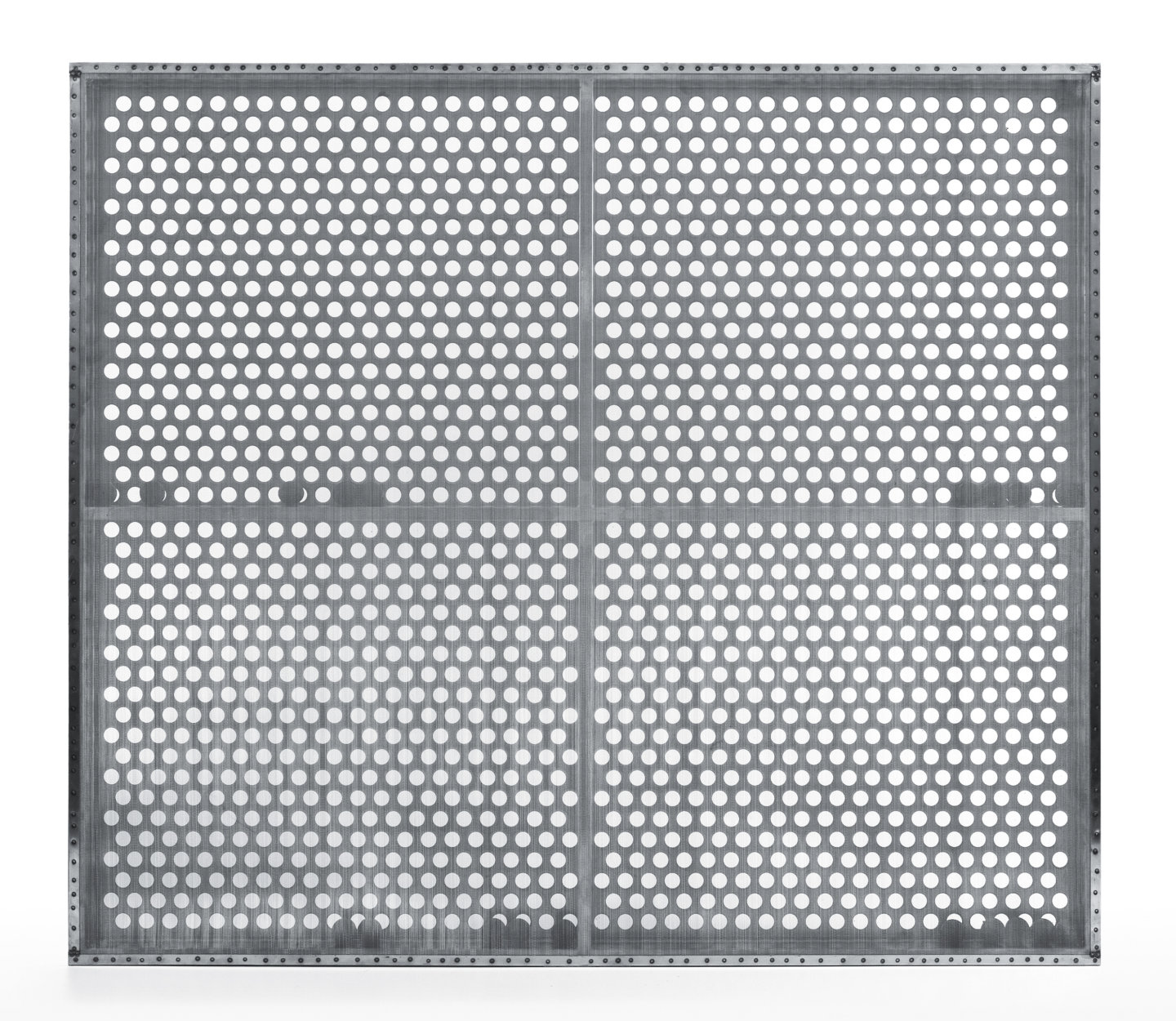

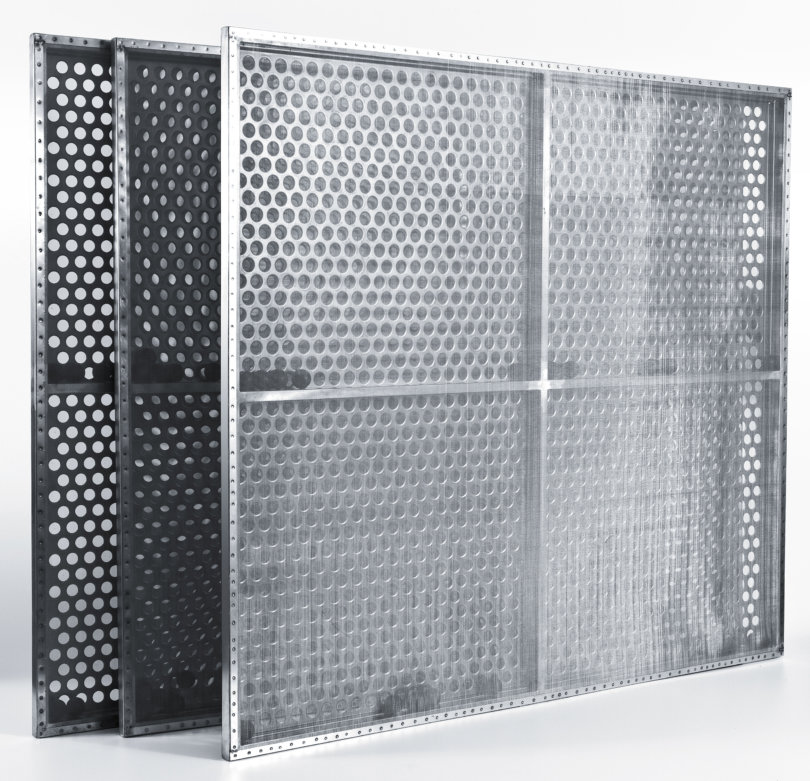

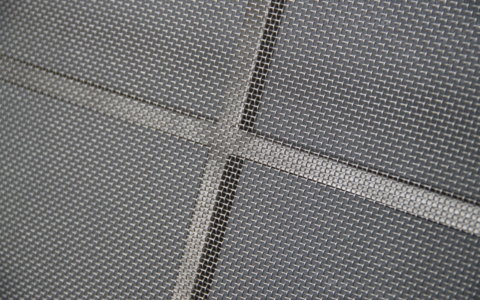

Rectangular screen frames (PAL type).

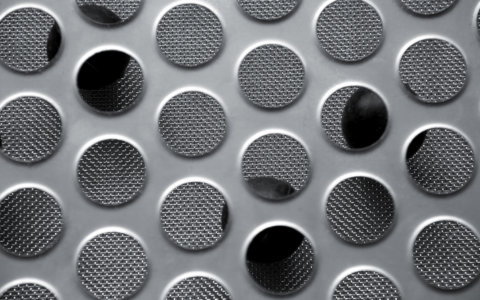

Available variants with a mesh or perforated working screen.

Parameters

We use the experience of our engineers and our R&D Centre to improve and develop product and material solutions.

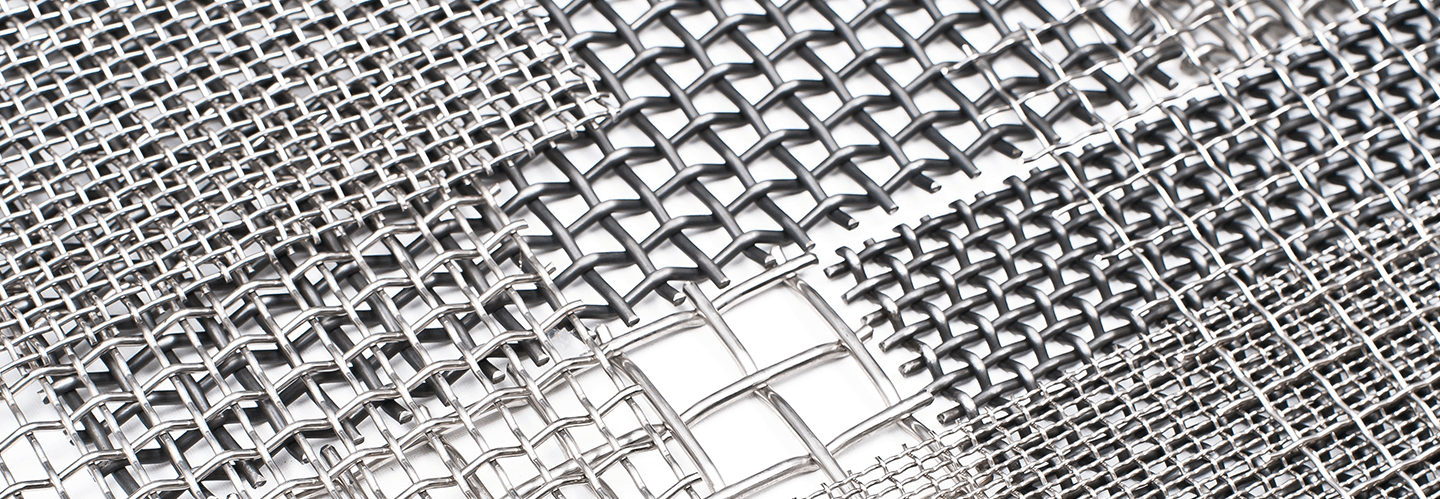

At present, we offer PROGRESS woven screens with mesh dimension 1.0 – 100 mm and wire diameters 0.8 – 6.3 mm.

At the Customer’s special request, we manufacture wire screens with different weft and warp diameters.

Maximum diameter of round frames: 2650 mm

Maximum format of rectangular frames: 4000×4000 mm

We provide technical information to individual requests for quotation.

Materials

Woven screens that operate under different conditions call for the use of top quality steels: black, spring, stainless, acid resistant, heat resistant and kanthal, inconel or duplex. Our material policy ensures their immediate availability and the support by our Design and Engineering Department ensures their optimum selection.