Do you need a screen to classify materials with high humidity and low flowability? Use the potential of PROGRESS harp screens. The special shape of the wires and the way they are joined provides the effect of self-cleaning even with a very demanding feed. The self-oscillation of the wires eliminates screening. PROGRESS SCREENS™ provides screens with hooks for mounting on all types of screens and sorters.

Products

Back

Harp screens

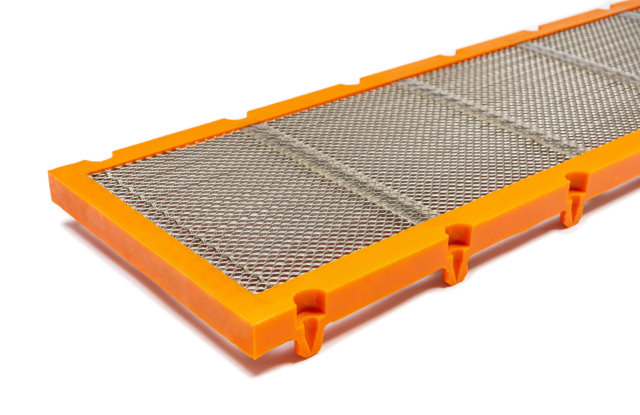

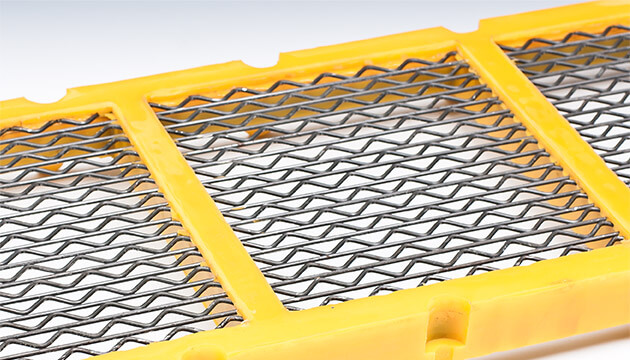

Pro-Clin modular panel with harp screen

Pro-Clin modular panel with harp screen

Tensioned harp screens

Tensioned harp screens

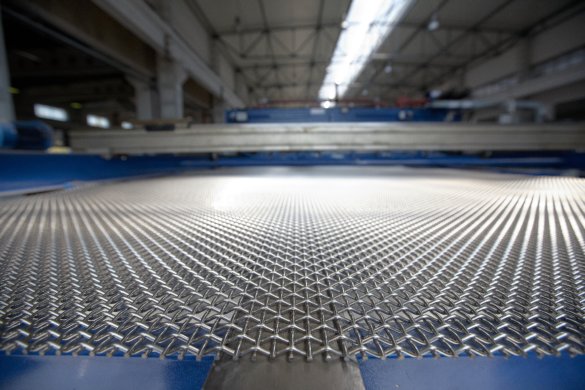

Harp screens - triangular mesh

Harp screens - triangular mesh

Harp screens - rubber and steal patches

Harp screens - rubber and steal patches

PROGRESS SCREENS™ Applications

Screens to the vibrating screening machines

Screens for sorters

Product advantages

Use the potential of PROGRESS

harp screens in screening and classification processes:

- Self-cleaning effect

- High ratio of open area

- Extended lifetime

- Wide range of openings and wire diameters

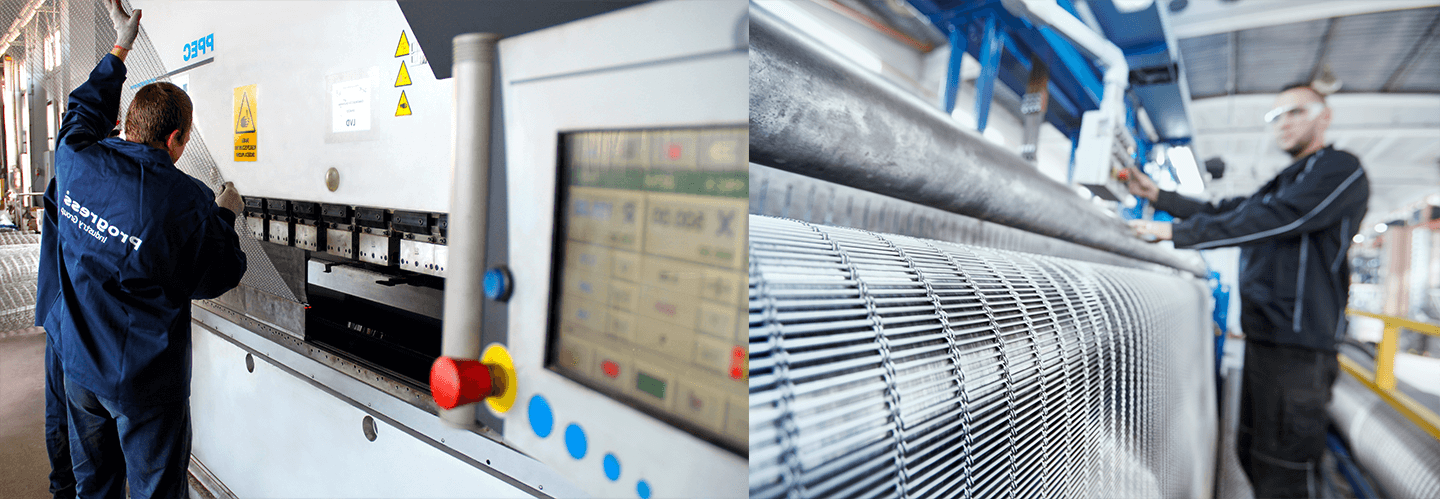

Manufacturing technologies

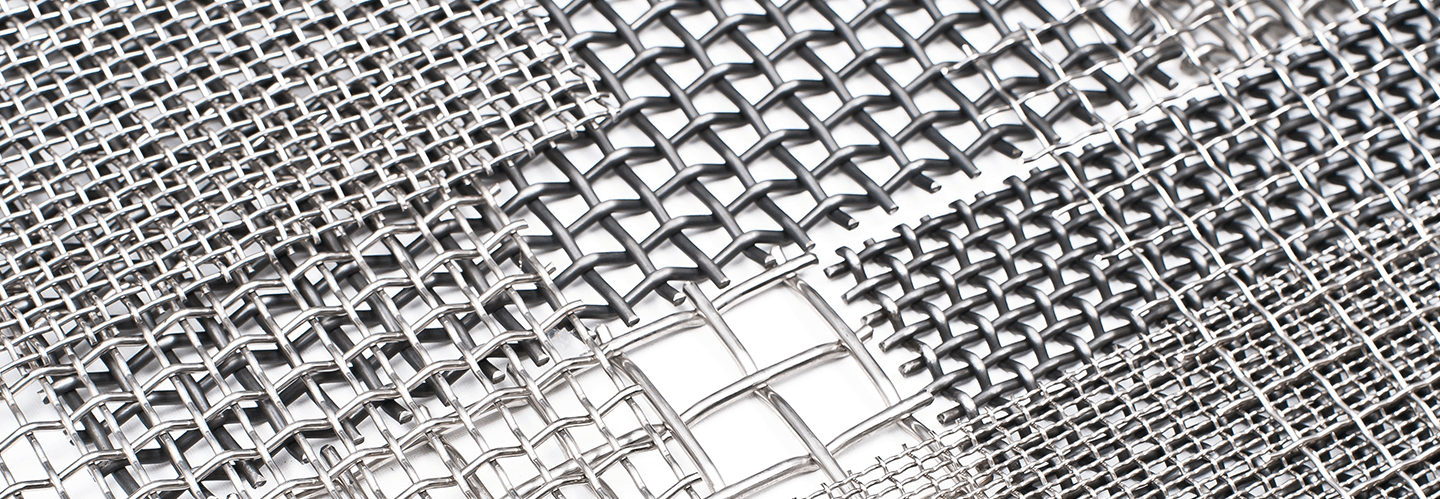

Using specialised knowledge and a modern machinery park, harp screens are made in the form of screens with TYP-T triangular and TYP-K square opening. Depending on the working conditions, we recommend the use of metal, rubber or polyurethane bands.

TYP-T harp screens

Harp screens with a triangular opening are perfect for screens that require a strong tension

TYP-K harp screens

Harp screens with a square opening use only precrimped wires, increasing the self-cleaning ability

Flat wire harp screens

The use of flat wire increases load resistance, extends service life and increases screening efficiency

Parameters

In the improvement and development of product and material solutions, we use the experience of our engineers and our own Research and Development Centre.

Currently, harp screens with triangular opening TYP T are offered in the range of 1.2 – 20 mm openings and wire diameter 0.8 – 6.3 mm.

Currently, harp screens with TYP-K triangular openings are offered in the range of 1.8 – 35 mm openings and wire diameter 0.8 – 4.5 mm.

We provide detailed technical information in respect of individual requests.

Ferrules and finishes

A wide range of brackets for transversal and longitudinal tension ensures proper installation of PROGRESS woven screens on all types of sifters and sorters.

Materials

The woven screens used in various conditions require the use of the highest quality spring, stainless and acid resistant steel. Their immediate availability is ensured by our material policy, and optimal selection by support of our Construction and Technology Department.