Inserts for screw presses are designed for the separation and dewatering of solid suspension particles. Precision manufacturing ensures high durability and high efficiency of the separation processes. We design and manufacture inserts for various types and models of equipment.

Products

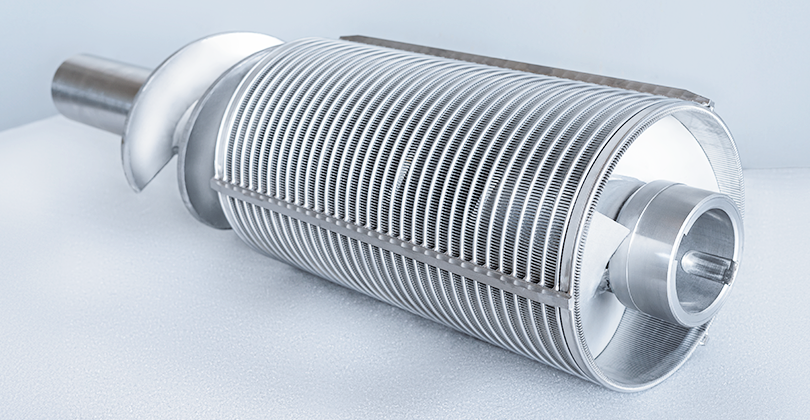

Pro-SLOT® wedge wire inserts for screw presses and separators

Application

Screw presses and separators

Industries

Biogas plants

Agriculture

Plastics recycling

Waste water treatment plants

Meat and poultry processing

Fruit and vegetable processing

Brewing

Application benefits

- Improved efficiency and accuracy of the separation process

- Reduction of raw material and material losses

- Continuity of production thanks to resistance to high overloads

- Dimensions and parameters adapted to the type and model of machine

- Precise manufacture within tight tolerances

Fast order processing

We provide professional service and fast order processing for Pro-SLOT® wedge wire inserts for screw presses and separators. For selected models, we offer the possibility to buy directly from stock and to purchase a set with auger. This shortens the delivery time of your order as much as possible.

Production technologies

Inserts for screw presses and separators are manufactured on the basis of RW-type cylinders made from Pro-SLOT® slotted screen of our own production. This is a cylinder with an internal inflow and a slot parallel to the axis. For selected press models, we also make worms to ensure a perfect fit with the slotted inserts.

Technical specifications

- Slot range: from 0.1mm

- Working profiles: 22Sb-42Sb, others by individual agreement

- Support cross section: D45, wire Ø6, Q55, others by individual agreement

- Dimensions and tolerances: by individual arrangement

- Materials: 1.4301, 1.4404, 1.4373

We manufacture inserts for manufacturers of screw presses and separators (OEM).

We actively cooperate with manufacturers of screw presses and separators. A dedicated team of engineers and technologists works on the implementation, development and improvement of inserts. Technical facilities in the form of our own materials laboratory, R&D department and state-of-the-art machinery allow us to create technologically and cost-optimised individual solutions.

Information on tolerances and process tests is available upon individual request.