Do you need durable and abrasion-resistant screens? Are you tired of fighting corrosion? Use the potential of polyurethane screens. Elastomer used for their production provides extended screen life, which works up to 10 times longer compared to steel screens. Thanks to these screens, you will reduce the number of costly downtimes. PROGRESS SCREENS™ provides solutions for all types of sifters and sorting equipment for ‘dry’ and ‘wet’ work.

Products

Back to the list

MODULAR POLYURETHANE SCREENS

Polyurethane screens - thermoplastic

Polyurethane screens - thermoplastic

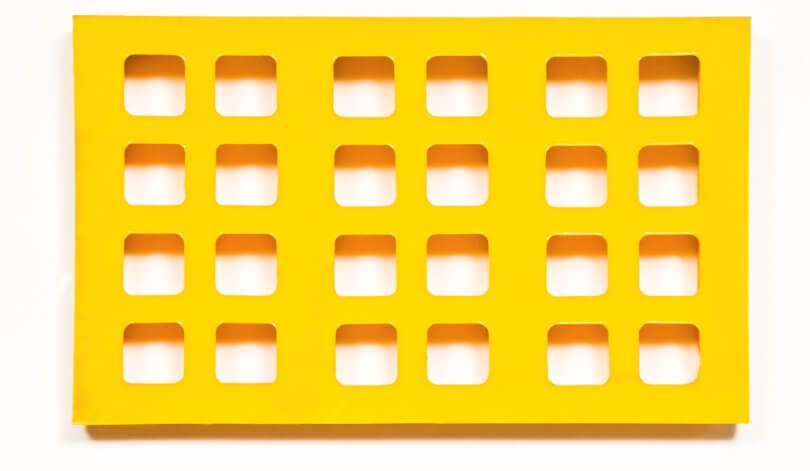

Polyurethane screens - square mesh

Polyurethane screens - square mesh

Polyurethane modular screens for screeners

Polyurethane modular screens for screeners

Polyurethane screens for wet screening

Polyurethane screens for wet screening

Polyurethane modular screens - Pro-Line

Polyurethane modular screens - Pro-Line

Polyurethane modular screens - Pro-DECK

Polyurethane modular screens - Pro-DECK

Polyurethane modular screens - Pro-CLEAT

Polyurethane modular screens - Pro-CLEAT

Polyurethane modular screens - PRO-CLIN

Polyurethane modular screens - PRO-CLIN

PROGRESS SCREENS™ Applications

Rotary drum screens

Screen decks

Industries

Product advantages

Use the potential of polyurethane screens in screening and classification processes:

- ‘wet’ and ‘dry’ work

- Resistance to abrasion and absence of corrosion

- Noise and dust reduction

- Possibility of exchanging individual modules

- Simple assembly and disassembly of modules

- Assembly systems

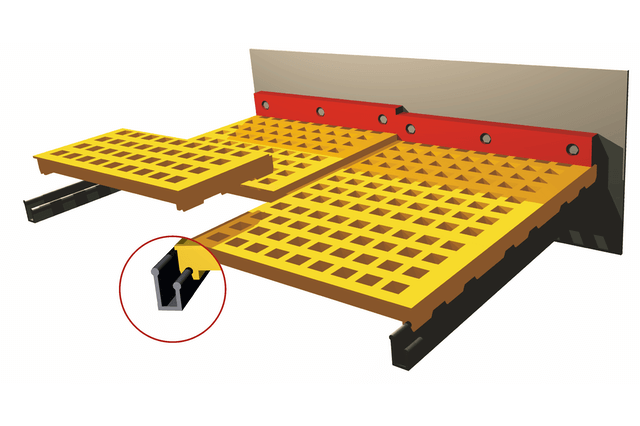

Assembly systems

Incorrect installation of the screen can shorten its life by up to 90%. PROGRESS SCREENS provides solutions for all types of screening and sorting equipment. It offers all the assembly systems available on the market and a wide range of fastening elements such as adapters, protective profiles, fastening wedges, side and pressure strips and others.

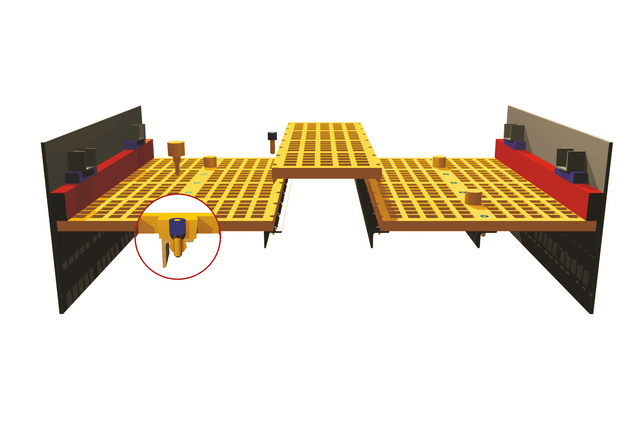

Pro-CLEAT® polyurethane screens

Modular polyurethane screens fastened by means of special pins

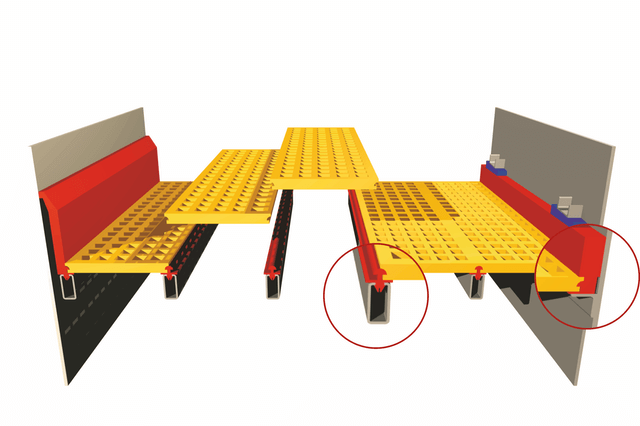

Pro-LINE® polyurethane screens

Modular polyurethane screens fastened by means of special strips

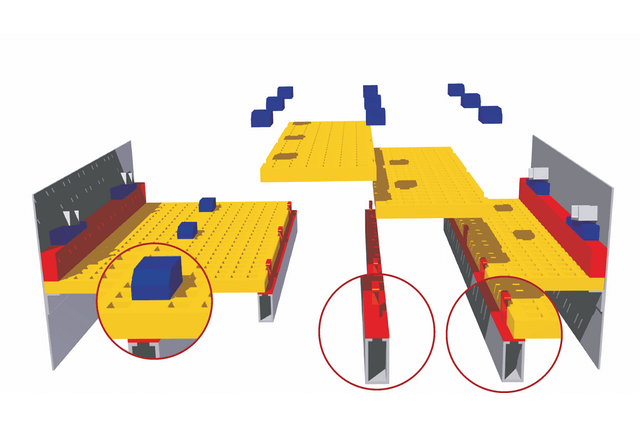

Pro-CLIN® polyurethane screens

Modular polyurethane screens fastened by means of special wedges

Sita poliuretanowe Pro-STEP®

Modular polyurethane screens fixed to the construction of two parallel rods of the riddle

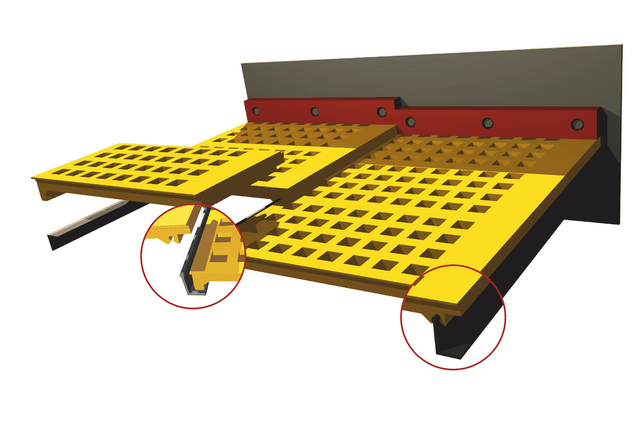

Pro-DECK® polyurethane screens

Modular polyurethane screens mounted on the rod and pressed by neighbouring modules to the riddle

Parameters

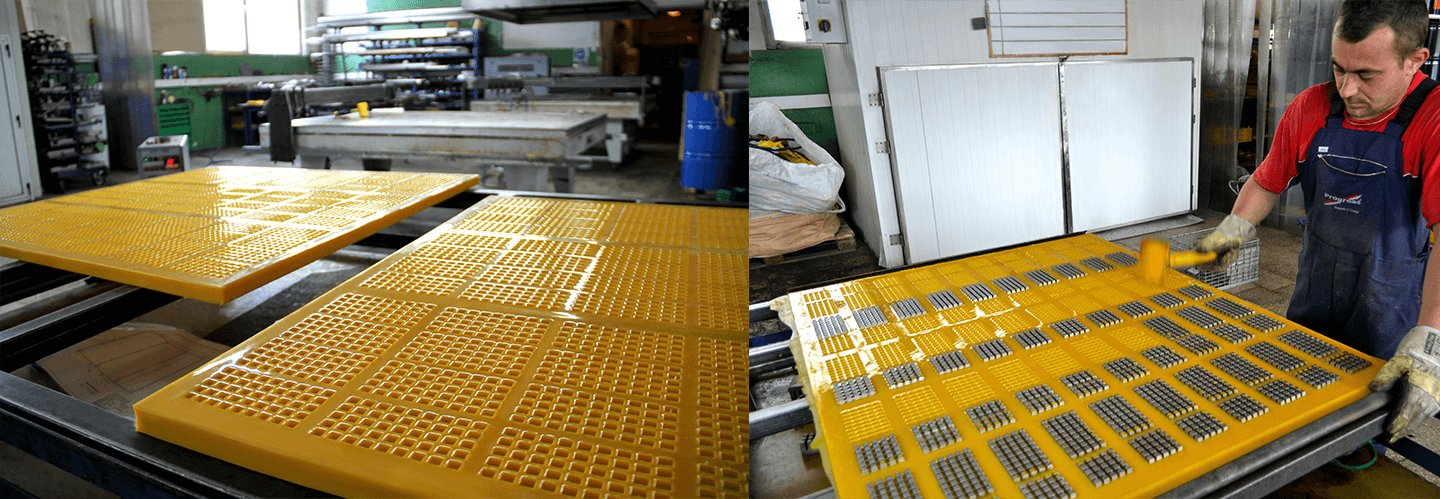

Using a modern machine park, we offer modular polyurethane screens in the openings range from 0.25 – 160 mm. The offer includes square and rectangular opening screens in a simple and passing layout.

The standard dimension of the central module is 300 x 1000 mm, and for external modules in accordance with the dimensions of the sifter or sorter. The standard screen thickness is 30 – 60 mm

We provide detailed technical information in respect of individual requests.

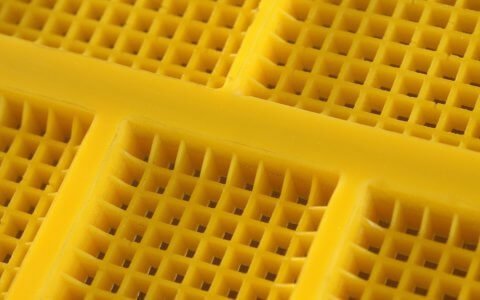

Reinforcements

Polyurethane screens are among the most durable industrial screens. Still, they cannot withstand particularly difficult working conditions and loads. We have a solution for this. PROGRESS SCREENS offers the possibility of using additional reinforcements in the form of metal rods and flat bars that are specially embedded in the screens.

Materials

Polyurethane screens operating under various conditions require the use of appropriate elastomers and optimal hardness. PROGRESS SCREENS offers solutions using polyurethane elastomers type A and B in the hardness range 45-95 Sh. Benefit from the advice of our sales engineer.