Do you require high precision in processing? Do you need screens capable of carrying heavy loads or pressures? Take advantage of Pro-SLOT® brand wedge wire screens potential. Thanks to the unique design and a wide range of profiles and parameters, they are ideal for mechanical filtration and separation of liquids and solids. PROGRESS SCREENS® provide an individual solutions for all types of machines and devices.

Products

Back

Pro-SLOT® wedge wire screens

Pro-SLOT® wedge wire screen Pro-CLIN system

Pro-SLOT® wedge wire screen Pro-CLIN system

Pro-SLOT® drum screen (FITO)

Pro-SLOT® drum screen (FITO)

Pro-SLOT® wedge wire filter screen

Pro-SLOT® wedge wire filter screen

Pro-SLOT® wedge wire screw press screen

Pro-SLOT® wedge wire screw press screen

Pro-SLOT® wedge wire snow cannon screen

Pro-SLOT® wedge wire snow cannon screen

Pro-SLOT® wedge wire laterals

Pro-SLOT® wedge wire laterals

Pro-SLOT® wedge wire bent screen

Pro-SLOT® wedge wire bent screen

Pro-SLOT® wedge wire reinforced bent screen

Pro-SLOT® wedge wire reinforced bent screen

Pro-SLOT® wedge wire mash tun floor

Pro-SLOT® wedge wire mash tun floor

Vibrating wedge wire screen Pro-CLIN system

Vibrating wedge wire screen Pro-CLIN system

Pro-SLOT® wedge wire screens – looped/flat

Pro-SLOT® wedge wire screens – looped/flat

Pro-SLOT® wedge wire screens – looped/curved

Pro-SLOT® wedge wire screens – looped/curved

Application

Screens to the vibrating screening machines

Rotary drum screens

Screen decks

Inserts for curved screens (static rundown screens)

Baskets for centrifuges Inserts for drum screeners

Inserts for screw presses

Floors for vats

Floors for tanks

Floors for reactors

Reactor elements

Elements for styrofoam chambers

Inserts for pressure filters

Inserts for self-cleaning filters

Inserts for candle filters

Inserts for axial filters

Inserts for angle filters

Filtration inserts

Filtration columns

Product advantages

Take advantage of the unique features of Pro-SLOT® wedge wire screens in your technological processes:

- Perfectly smooth and flat surface

- Self-cleaning ability

- Low pressure drop

- Carrying heavy loads

- Extended lifetime

- Manufacturing technologies

Manufacturing technologies

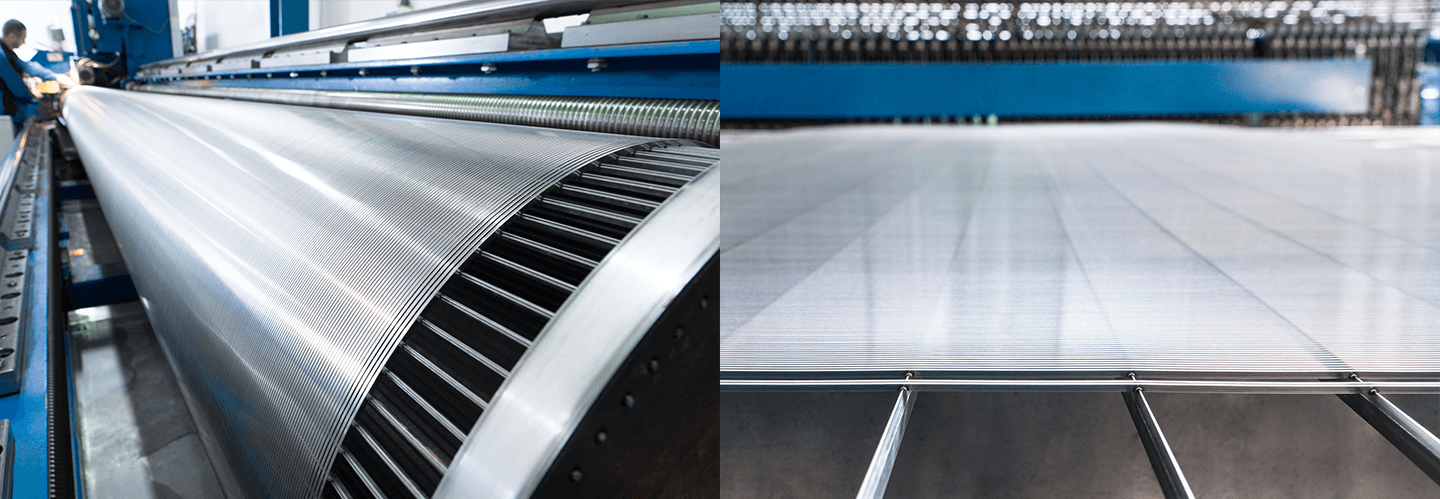

Using our modern machine park, Pro-SLOT® wedge wire screens are produced both in ‘flat’ and ‘round’ welding technology. Depending on the application and its individual parameters, our technologist decides about its selection.

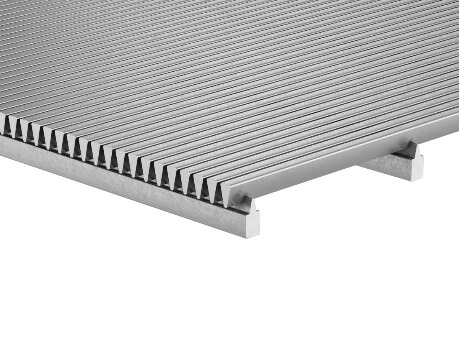

Pro-SLOT® wedge wire screens – flat

The flat welding technology ensures flatness within small tolerances. It does not weaken joints, as in the case of straightening screens welded on a round.

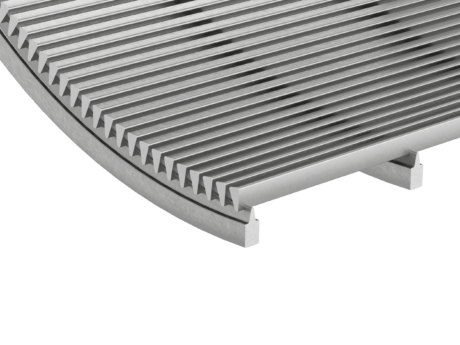

Pro-SLOT® wedge wire screens – bend

Curved wedge wire screens are made in both welding technologies. The specifics of the work and individual parameters determine the technology we use.

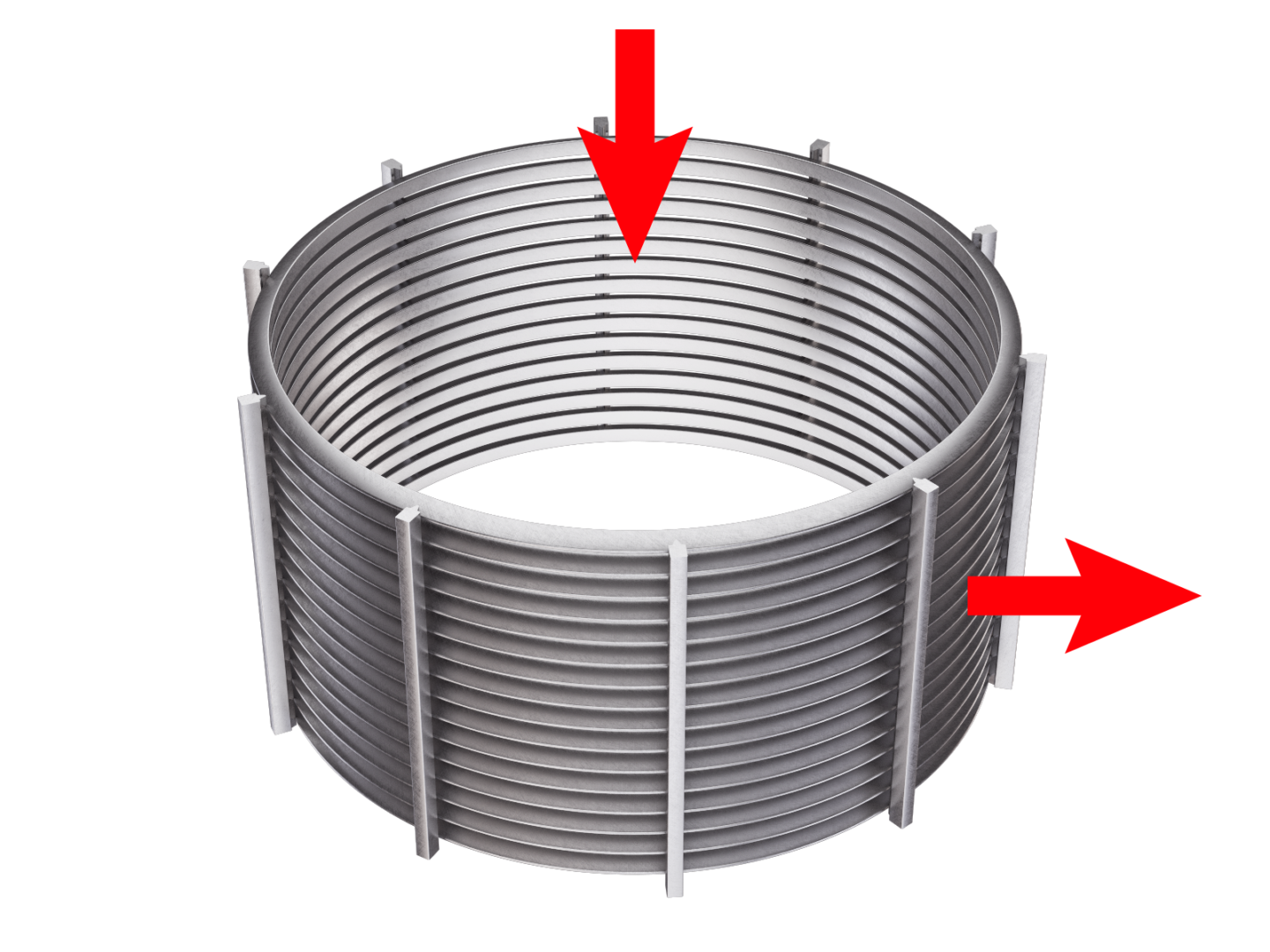

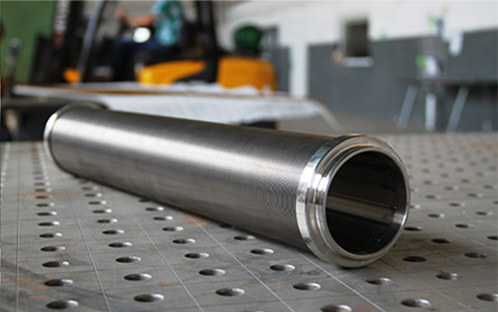

Pro-SLOT® wedge wire tubes – OZ / FOTI

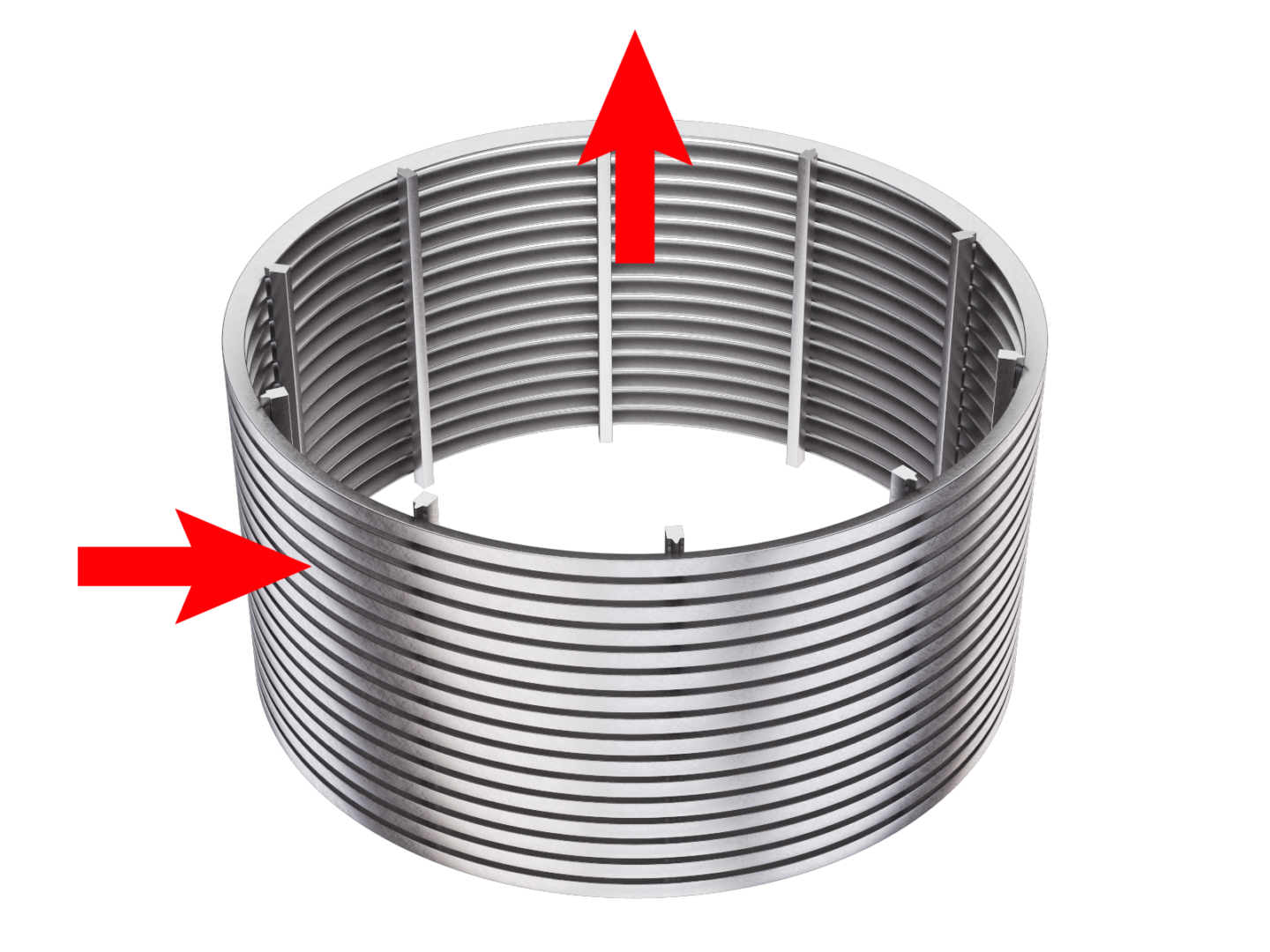

OZ type slotted tubes have a circumferential gap perpendicular to the longitudinal axis of the cylinder. Used in filtration from outside to inside. The inlet side of the filter remains smooth and easy to clean

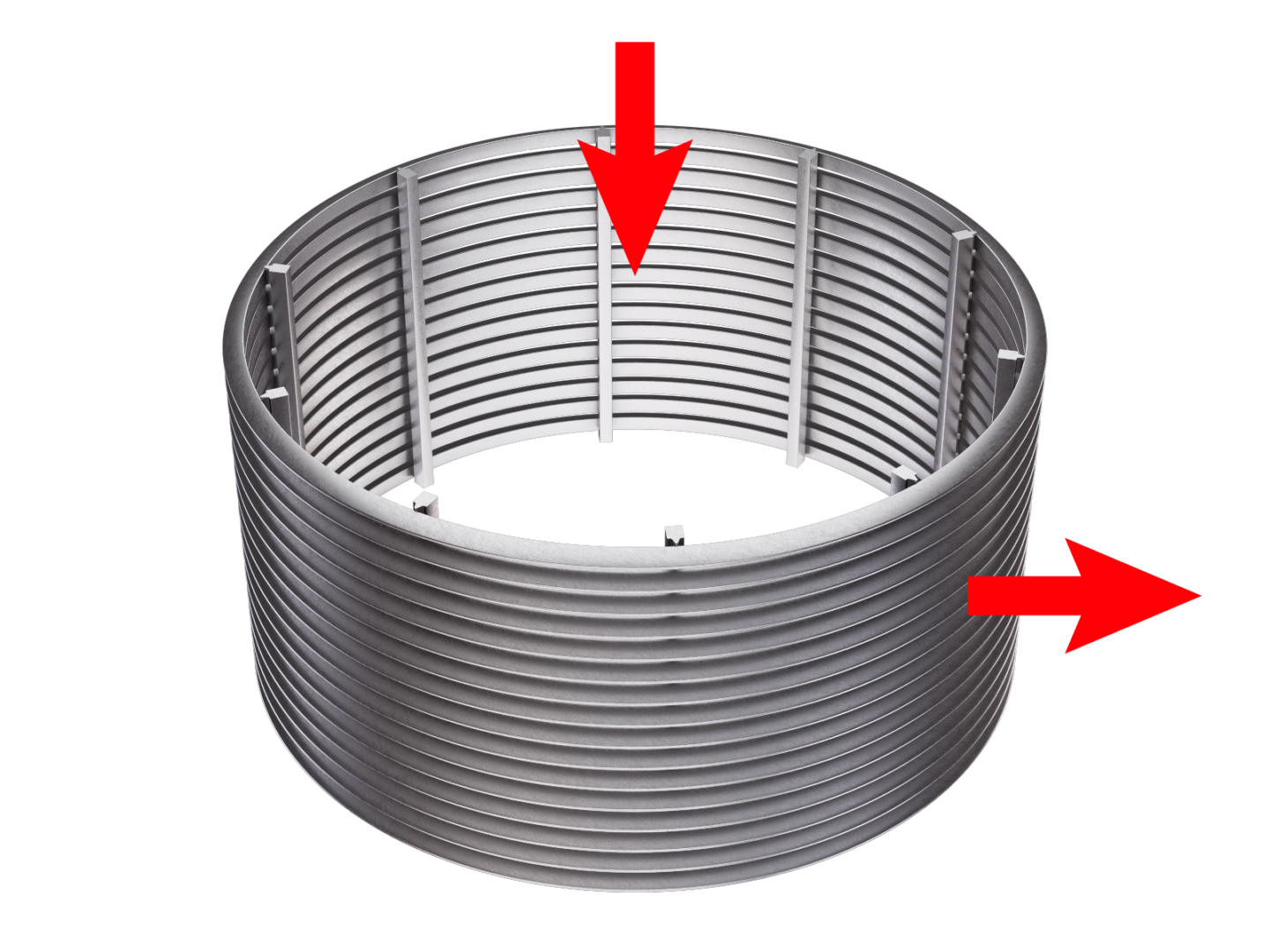

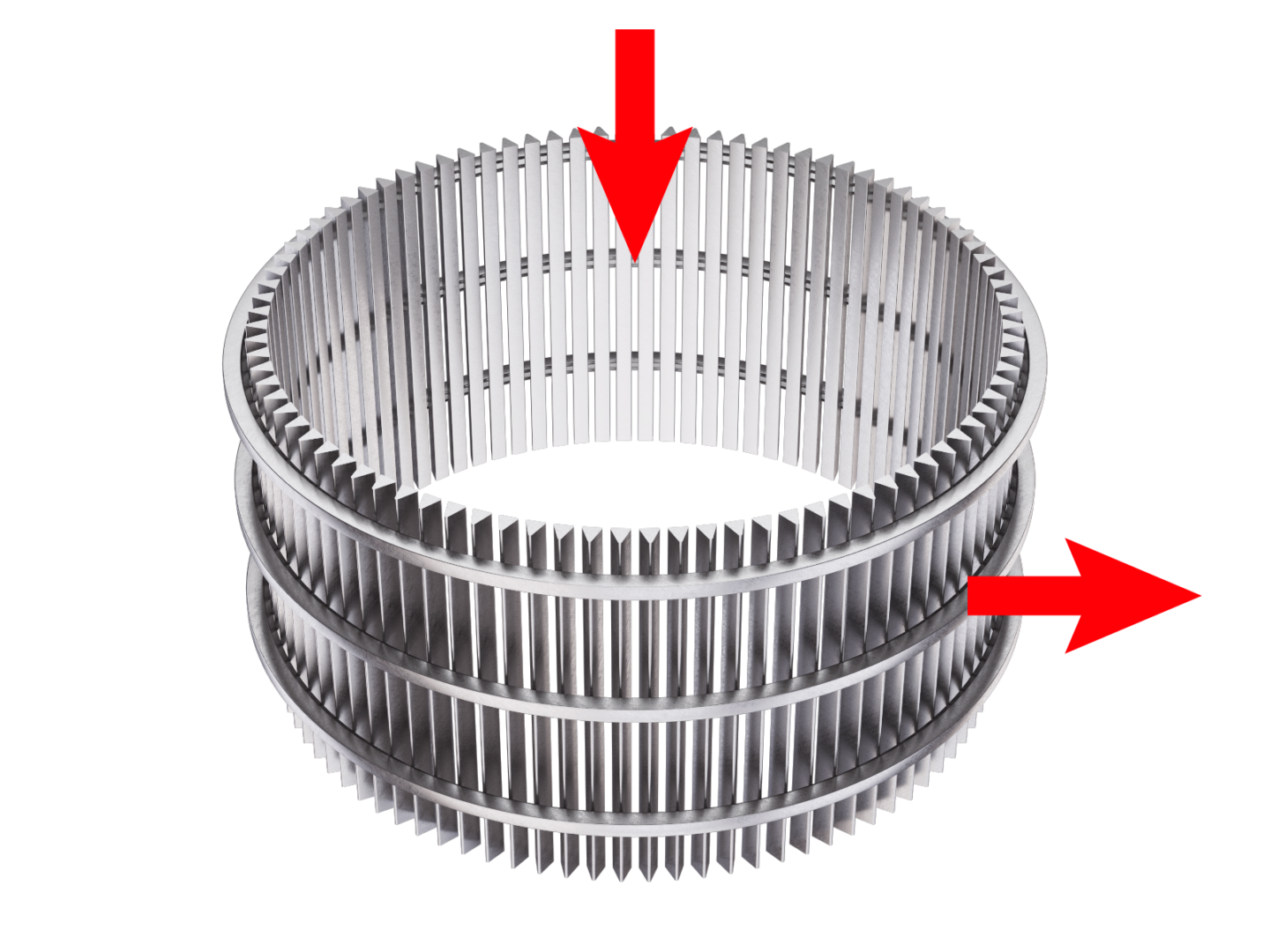

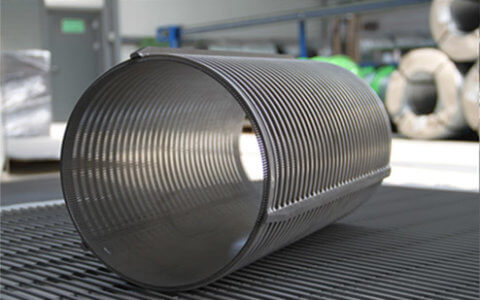

Pro-SLOT® wedge wire tubes – OZR / FITO

OZR wedge wire tubes have a peripheral slot perpendicular to the longitudinal axis of the cylinder. Used in filtration from inside to inside. The inlet side of the filter remains smooth and easy to clean

Pro-SLOT® wedge wire tubes – RW / FOTI

RW wedge wire tubes have a slot parallel to the longitudinal axis of the cylinder. Used in filtration from outside to inside. The inlet side of the filter remains smooth and easy to clean

Pro-SLOT® wedge wire tubes – OW / FOTI / FITO

OW wedge wire tubes have a peripheral slot perpendicular to the axis of the cylinder. Used in filtration from outside to inside. The inlet side of the filter remains smooth and easy to clean

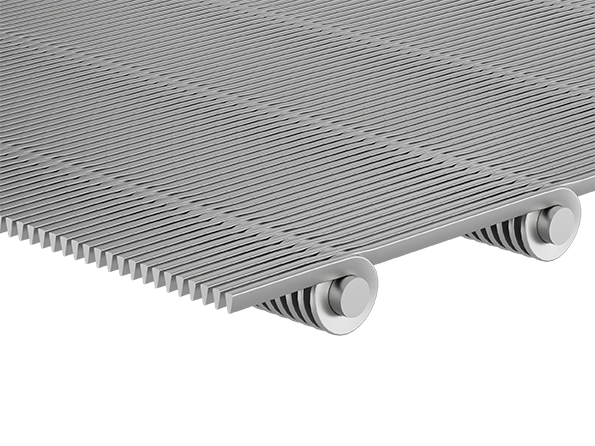

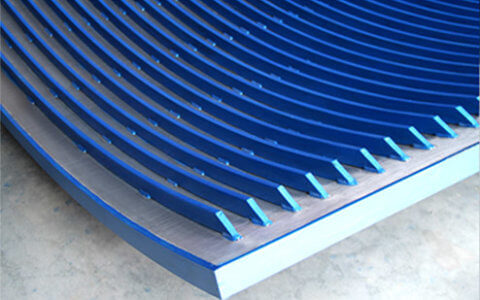

Pro-SLOT® wedge wire screens – looped / flat

Are created by plastic deformation on round wire presses. After achieving the required parameters, the wires are placed next to each other and connected by a crossbar passing through the loops.

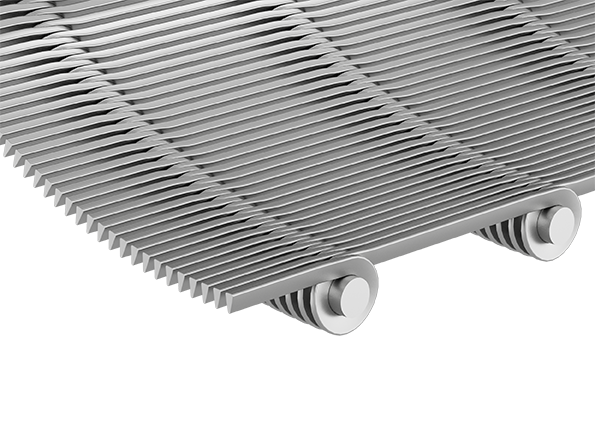

Pro-SLOT® wedge wire screens – looped / curved

We manufacture looped wedge wire screens in the form of bent plates with the possibility of reinforcement with additional fittings and fastening elements.

Parameters

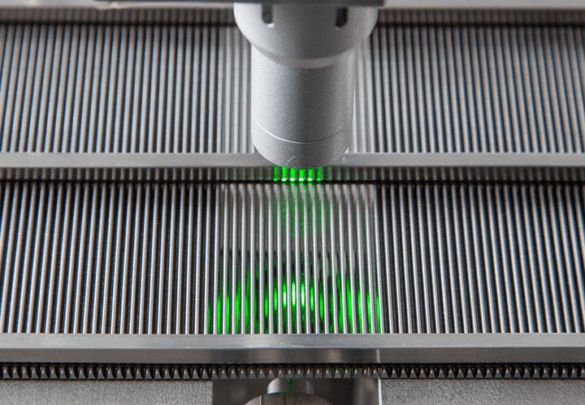

Using precision welding machines, we offer Pro-SLOT® wedge wire screens with slot dimensions from 40 um. For flat-welded screens, we offer a maximum size of 3000 x 3000 mm, and for wedge wire tubes round welded a maximum length of 6000 mm. We provide tolerance information in respect of individual enquiries.

Wedge wire profiles and support rods

Are you unsure about which profiles work best? Our constructors will choose the right shape, size and spacing depending on individual applications, working conditions and design assumptions. In order to reduce the manufacturing time, PROGRESS SCREENS® ensures availability of a wide range of profiles in various material solutions.

Wedge wire profile types Sb6, Sb8, Sb10, Sb12, Sb18, Sb22, Sb28, Sb/Sbb34, Sbb38, Sb/Sbb42, SbA/Sbb50,Sb55, Sbb76, 2,4×5, 3×6,5

Support rod types 10×3, 10×2, 12×3, 15×3, 18×2, 20×2, 30×2, 38×2, Q25, Q35, Q55, D45

Materials

Industrial sieves work in diverse conditions and with different media. That is why it is so important to choose the right material for your individual needs. PROGRESS SCREENS® offers a wide range of solutions in stainless, acid-proof and heat-resistant steels as well as special steels. We dedicate the hardest challenges to HARD-ECO™ steel.